The integration of Underfloor Air Distribution (UFAD) and Raised Access Flooring (RAF) systems in Mass Timber construction projects is transforming building design, construction and performance. These innovative solutions, paired with the environmental and structural advantages of mass timber, offer an advanced approach to indoor air quality, building flexibility, and sustainability. This article explores how UFAD and RAF systems are enhancing mass timber buildings, promoting energy efficiency, comfort, and versatility.

Mass timber has gained significant profile as a sustainable and high-performance alternative to steel and concrete construction. Offering a compelling aesthetic appeal, several environmental benefits, and reduced carbon footprint, mass timber is making its mark in modern construction, particularly in mid- to high-rise buildings.

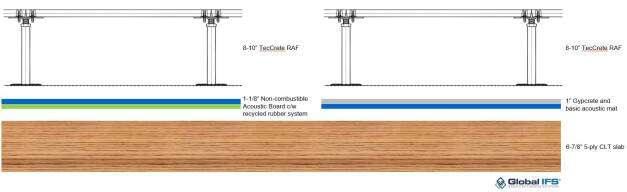

As a lightweight material, wood systems often integrate acoustic treatments to meet the level of acoustic performance required. Integrating mechanical systems with exposed structural elements—while also incorporating acoustic assemblies—can present architectural and building systems design challenges. UFAD and RAF can play a role in addressing many of these challenges.

FEATURE

Underfloor Air Distribution & Raised Access Flooring in Mass Timber Buildings

Scroll to Read

At Moriyama Teshima Architects, we often utilize underfloor air distribution (UFAD) systems as part of our commitment to high-performance sustainable design. UFAD systems…reduce overall fan energy, take advantage of natural thermal stratification and significantly improve HVAC performance. As a firm that specializes in mass timber, UFAD supports clean, unobstructed ceiling designs by eliminating the need for extensive overhead ductwork, cable trays and mechanical piping. This not only enhances visual clarity and ceiling height but also creates flexible, adaptable spaces which is an important consideration in educational, institutional, and civic projects where future reconfiguration is likely.

Phil Silverstein, Partner, Moriyama Teshima Architects

By Jesse Foden, New Business Development Canada, Camino Systems

How Raised Access Flooring (RAF) Supports UFAD Systems

In combination with UFAD systems, RAF offers the following advantages:

Flexibility: The system allows for easy reconfiguration of air distribution, power outlets, and data connections without extensive downtime or disruption. This flexibility is particularly valuable in open-plan offices or multi-use spaces, where the arrangement of spaces can change over time.

Energy Efficiency: By using UFAD, the need for high ceilings or large, traditional ductwork is eliminated, reducing the overall building height and materials needed, which in turn reduces energy consumption.

Space Efficiency: With the ability to house MEP systems within the raised floor cavity, RAF minimizes the need for vertical shaft space and reduces the footprint of mechanical systems in the building along with their visibility on exposed Mass Timber ceilings.

Ease of Maintenance: The accessibility of the raised floor allows quick and easy access to air distribution systems, electrical wiring, and communication cables, making repairs or upgrades less disruptive and more cost-effective.

Raised Access Flooring (RAF) refers to a flooring system elevated above the structural floor, creating a space (the plenum) for mechanical, electrical, and plumbing (MEP) systems. This raised platform can house cables, wiring, and air distribution ducts, and its design supports flexibility in the building's layout by making it easy to modify or reconfigure systems.

Underfloor Air Distribution (UFAD) is an HVAC (Heating, Ventilation, and Air Conditioning) system where conditioned air is supplied via Modular Air Towers or a central air handling unit to air plenum beneath the raised floor, instead of the traditional ceiling-mounted ductwork. UFAD circulates air via a network of pressurized floor plenum, in-floor diffusers (vents), and perimeter trench hydronic heat/cool systems embedded in the raised flooring, providing an efficient and adaptable way to distribute conditioned air throughout a building.

What is Underfloor Air Distribution (UFAD)?

In UFAD systems:

Air is delivered at floor level, directly into occupied spaces.

The air that is supplied at floor level gradually warms up from body and equipment heat, causing it to rise. This creates natural air circulation for ventilation, requiring significantly lower fan speeds (0.05wg of pressure vs. 2-3wg in an overhead system) and facilitating better thermal comfort.

Perimeter heat/cool systems temper increased cooling and heating loads at the curtain wall/perimeter of the building via hydronic or electric heating elements and the same conditioned air used to cool the interior zone diffusers.

Air recirculation is managed through the raised flooring and free flowing ceiling return system which can eliminate almost 90% of HVAC distribution branch ductwork on the project.

When paired with mass timber, UFAD and RAF systems complement each other in several ways:

Acoustic Comfort

The combination of mass timber and RAF can significantly improve the acoustics of a building. A RAF system can be installed above mass timber floor assemblies designed to absorb sound transmission through the floor, and reduce mechanical noise caused by traditional overhead ductwork. Additionally, the absence of overhead ducts or vents enhances the overall acoustic performance of the space.

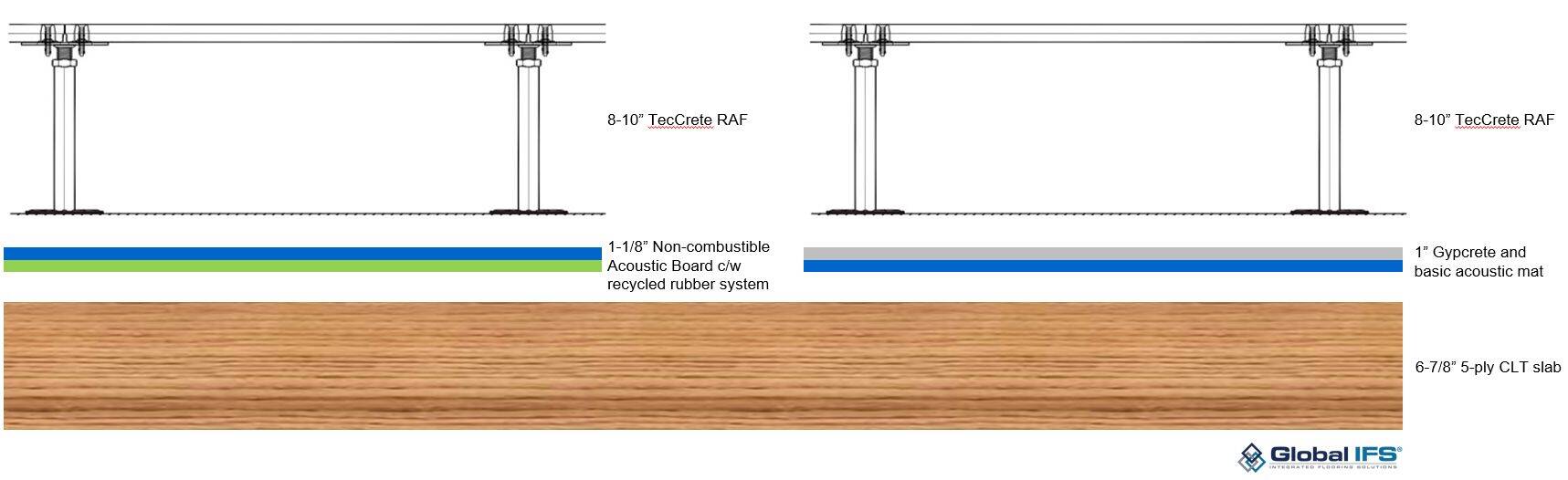

An additional benefit of deploying a RAF/UFAD solution is that you can significantly reduce the amount of concrete and acoustic matting required due to the acoustic performance of the RAF system and air gap/plenum.

Improved Indoor Air Quality (IAQ)

With UFAD, air is delivered at low velocities from the floor, reducing the likelihood of dust and pollutants circulating throughout the room. Additionally, the ability to control air distribution precisely allows for better indoor air quality, which is essential for occupant health and well-being.

Reduced allergens: By delivering air from the ground level, UFAD reduces the chances of allergens, dust, or contaminants being suspended in the air.

Localized cooling and heating: UFAD allows individual control over temperature zones, ensuring that occupants experience consistent and comfortable environmental conditions without the need for complex ductwork.

Enhanced Sustainability

Why Combine UFAD and RAF in Mass Timber Construction?

Mass timber already contributes to the building's sustainability through its low carbon footprint, and the integration of UFAD and RAF further enhances this by reducing the energy required for heating, cooling, and ventilation.

The UFAD system improves energy efficiency by harnessing natural convection, ensuring even airflow with reduced need for energy-intensive fans, offering an average of 20-30% more efficiency than traditional overhead HVAC systems.

The raised floor systems can support energy-efficient lighting, and electrical systems, and allow for integration of renewable energy systems like radiant cooling or heating.

Together, these elements combine to create a building with lower overall energy consumption, aligning with environmental goals such as reducing carbon emissions and lowering utility costs.

5

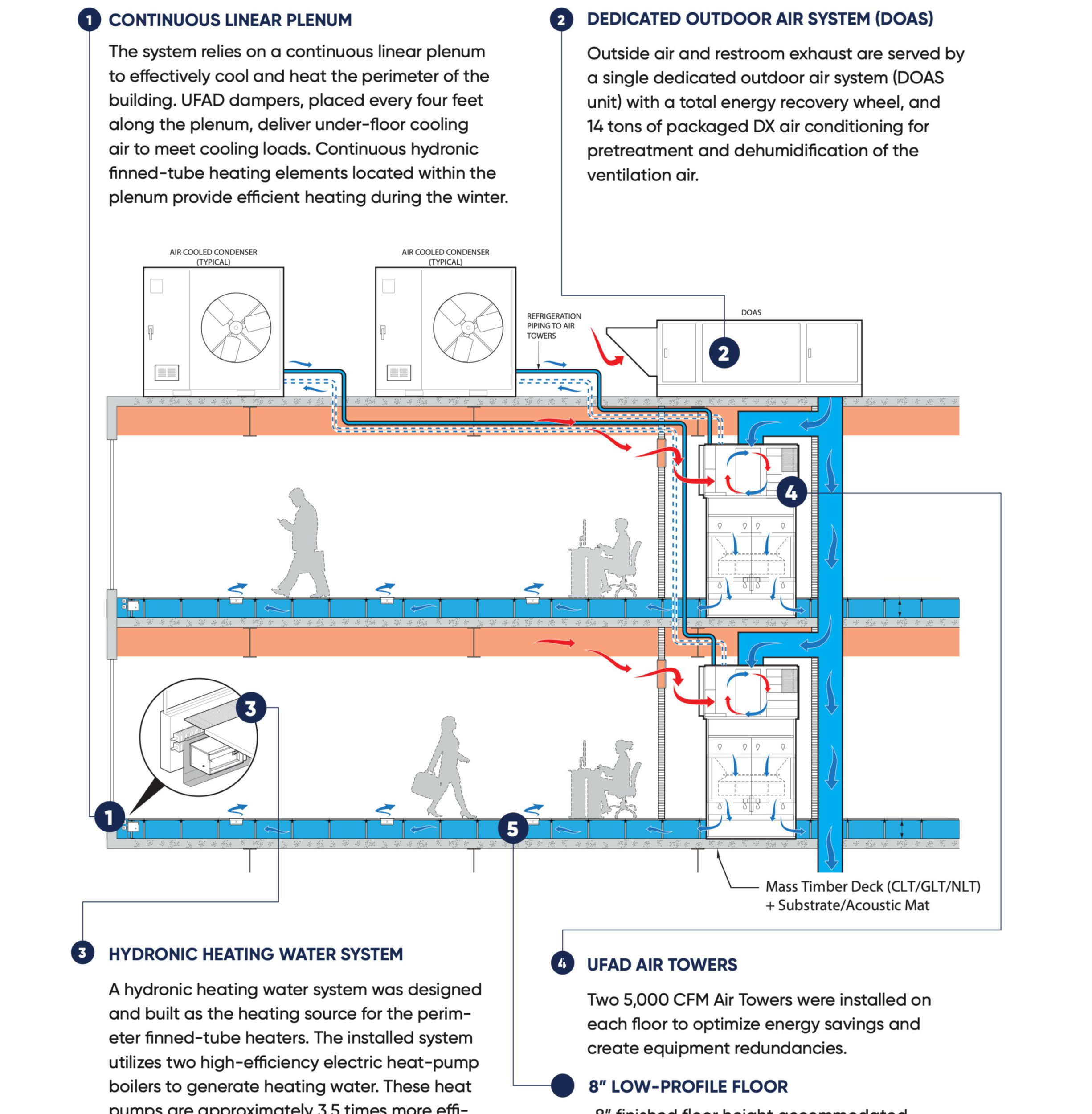

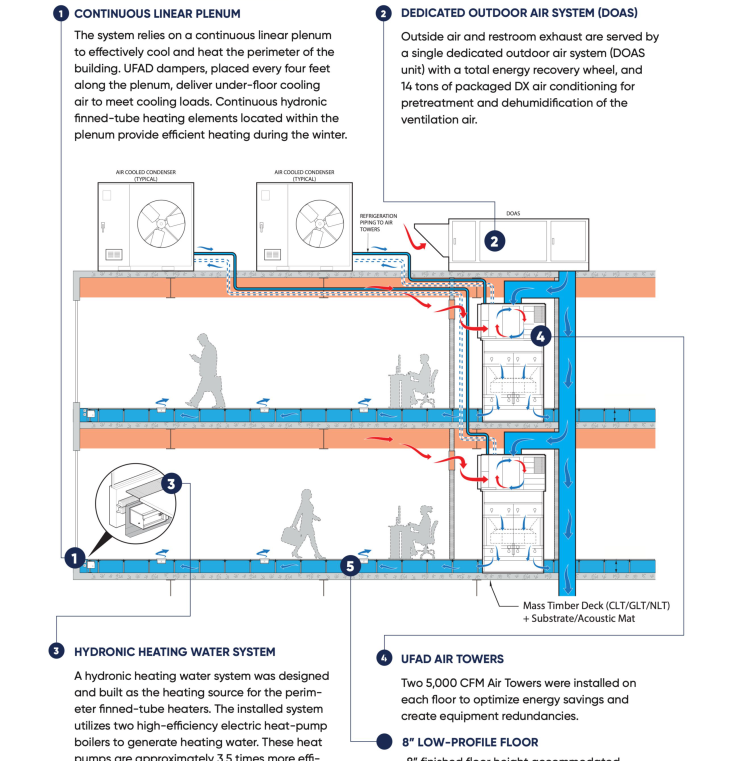

8" finished floor height accommodated interior zone diffusers (manually or automatically operated).

Two 5,000 CFM Air Towers were installed on each floor to optimize energy savings and create equipment redundancies.

A hydronic heating water system was designed and built as the heating source for the perimeter finned-tube heaters. The installed system utilizes two high-efficiency electric heat-pump boilers to generate heating water. These heat pumps are approximately 3.5 times more efficient than traditional electric strip heaters, and approximately 4 times more efficient than natural gas-fired boilers.

Outside air and restroom exhaust are served by a single dedicated outdoor air system (DOAS unit) with a total energy recovery wheel, and 14 tons of packaged DX air conditioning for pretreatment and dehumidification of the ventilation air.

The system relies on a continuous linear plenum to effectively cool and heat the perimeter of the building. UFAD dampers, placed every four feet along the plenum, deliver under-floor cooling air to meet cooling loads. Continuous hydronic finned-tube heating elements located within the plenum provide efficient heating during the winter.

System Components

Incorporating UFAD and RAF systems in mass timber buildings requires careful planning. Here are key considerations when integrating these systems into a project:

Space Planning: The raised floor system allows for maximum flexibility in how spaces are configured. This can be particularly valuable in areas where tenants may need to modify layouts more frequently, such as in office or commercial spaces.

MEP Integration: Coordination of the MEP system is essential to ensure that air ducts, wiring, and plumbing are integrated seamlessly into the raised floor, preventing conflicts with the timber structure.

Flooring Options: RAF tiles or segmented finishes like carpet tiles maintain easy access to the floor plenum.

Additionally, collaboration among architects, engineers, and contractors is critical to ensure that UFAD and RAF systems are effectively integrated with mass timber’s aesthetic and performance characteristics.

Designing for Efficiency:

How These Systems Fit in Mass Timber Projects

Designing for Efficiency:

How These Systems Fit in Mass Timber Projects

Incorporating UFAD and RAF systems in mass timber buildings requires careful planning. Here are key considerations when integrating these systems into a project:

Space Planning: The raised floor system allows for maximum flexibility in how spaces are configured. This can be particularly valuable in areas where tenants may need to modify layouts more frequently, such as in office or commercial spaces.

MEP Integration: Coordination of the MEP system is essential to ensure that air ducts, wiring, and plumbing are integrated seamlessly into the raised floor, preventing conflicts with the timber structure.

Flooring Options: RAF tiles or segmented finishes like carpet tiles maintain easy access to the floor plenum.

Additionally, collaboration among architects, engineers, and contractors is critical to ensure that UFAD and RAF systems are effectively integrated with mass timber’s aesthetic and performance characteristics.

Conclusion: A Harmonious Future for Mass Timber

As the construction industry embraces more sustainable building practices, the combination of Underfloor Air Distribution and Raised Access Flooring with Mass Timber represents a forward-thinking solution. These systems improve energy efficiency, air quality, and flexibility while enhancing the performance and aesthetics of timber buildings. The potential for reducing energy consumption and minimizing the carbon footprint is particularly important in today’s quest for more sustainable architecture.

Mass timber, paired with UFAD and RAF, has the power to transform how we approach the design of modern buildings—creating flexible, sustainable, and healthy environments for occupants while advancing the use of renewable materials. With these systems working together, the future of construction is undoubtedly green, innovative, and efficient.

Designing for Efficiency: How These Systems Fit in Mass Timber Projects

The integration of Underfloor Air Distribution (UFAD) and Raised Access Flooring (RAF) systems in Mass Timber construction projects is transforming building design, construction and performance. These innovative solutions, paired with the environmental and structural advantages of mass timber, offer an advanced approach to indoor air quality, building flexibility, and sustainability. This article explores how UFAD and RAF systems are enhancing mass timber buildings, promoting energy efficiency, comfort, and versatility.

Mass timber has gained significant profile as a sustainable and high-performance alternative to steel and concrete construction. Offering a compelling aesthetic appeal, several environmental benefits, and reduced carbon footprint, mass timber is making its mark in modern construction, particularly in mid- to high-rise buildings.

As a lightweight material, wood systems often integrate acoustic treatments to meet the level of acoustic performance required. Integrating mechanical systems with exposed structural elements—while also incorporating acoustic assemblies—can present architectural and building systems design challenges. UFAD and RAF can play a role in addressing many of these challenges.

Incorporating UFAD and RAF systems in mass timber buildings requires careful planning. Here are key considerations when integrating these systems into a project:

Space Planning: The raised floor system allows for maximum flexibility in how spaces are configured. This can be particularly valuable in areas where tenants may need to modify layouts more frequently, such as in office or commercial spaces.

MEP Integration: Coordination of the MEP system is essential to ensure that air ducts, wiring, and plumbing are integrated seamlessly into the raised floor, preventing conflicts with the timber structure.

Flooring Options: RAF tiles or segmented finishes like carpet tiles maintain easy access to the floor plenum.

Additionally, collaboration among architects, engineers, and contractors is critical to ensure that UFAD and RAF systems are effectively integrated with mass timber’s aesthetic and performance characteristics.

Underfloor Air Distribution (UFAD) is an HVAC (Heating, Ventilation, and Air Conditioning) system where conditioned air is supplied via Modular Air Towers or a central air handling unit to air plenum beneath the raised floor, instead of the traditional ceiling-mounted ductwork. UFAD circulates air via a network of pressurized floor plenum, in-floor diffusers (vents), and perimeter trench hydronic heat/cool systems embedded in the raised flooring, providing an efficient and adaptable way to distribute conditioned air throughout a building.

FEATURE

Underfloor Air Distribution & Raised Access Flooring in Mass Timber Buildings

By Jesse Foden, New Business Development Canada, Camino Systems

Conclusion: A Harmonious Future for Mass Timber

As the construction industry embraces more sustainable building practices, the combination of Underfloor Air Distribution and Raised Access Flooring with Mass Timber represents a forward-thinking solution. These systems improve energy efficiency, air quality, and flexibility while enhancing the performance and aesthetics of timber buildings. The potential for reducing energy consumption and minimizing the carbon footprint is particularly important in today’s quest for more sustainable architecture.

Mass timber, paired with UFAD and RAF, has the power to transform how we approach the design of modern buildings—creating flexible, sustainable, and healthy environments for occupants while advancing the use of renewable materials. With these systems working together, the future of construction is undoubtedly green, innovative, and efficient.

At Moriyama Teshima Architects, we often utilize underfloor air distribution (UFAD) systems as part of our commitment to high-performance sustainable design. UFAD systems…reduce overall fan energy, take advantage of natural thermal stratification and significantly improve HVAC performance. As a firm that specializes in mass timber, UFAD supports clean, unobstructed ceiling designs by eliminating the need for extensive overhead ductwork, cable trays and mechanical piping. This not only enhances visual clarity and ceiling height but also creates flexible, adaptable spaces which is an important consideration in educational, institutional, and civic projects where future reconfiguration is likely.

Phil Silverstein, Partner, Moriyama Teshima Architects

When paired with mass timber, UFAD and RAF systems complement each other in several ways:

How Raised Access Flooring (RAF) Supports UFAD Systems

In combination with UFAD systems, RAF offers the following advantages:

Flexibility: The system allows for easy reconfiguration of air distribution, power outlets, and data connections without extensive downtime or disruption. This flexibility is particularly valuable in open-plan offices or multi-use spaces, where the arrangement of spaces can change over time.

Energy Efficiency: By using UFAD, the need for high ceilings or large, traditional ductwork is eliminated, reducing the overall building height and materials needed, which in turn reduces energy consumption.

Space Efficiency: With the ability to house MEP systems within the raised floor cavity, RAF minimizes the need for vertical shaft space and reduces the footprint of mechanical systems in the building along with their visibility on exposed Mass Timber ceilings.

Ease of Maintenance: The accessibility of the raised floor allows quick and easy access to air distribution systems, electrical wiring, and communication cables, making repairs or upgrades less disruptive and more cost-effective.

Raised Access Flooring (RAF) refers to a flooring system elevated above the structural floor, creating a space (the plenum) for mechanical, electrical, and plumbing (MEP) systems. This raised platform can house cables, wiring, and air distribution ducts, and its design supports flexibility in the building's layout by making it easy to modify or reconfigure systems.

In UFAD systems:

Air is delivered at floor level, directly into occupied spaces.

The air that is supplied at floor level gradually warms up from body and equipment heat, causing it to rise. This creates natural air circulation for ventilation, requiring significantly lower fan speeds (0.05wg of pressure vs. 2-3wg in an overhead system) and facilitating better thermal comfort.

Perimeter heat/cool systems temper increased cooling and heating loads at the curtain wall/perimeter of the building via hydronic or electric heating elements and the same conditioned air used to cool the interior zone diffusers.

Air recirculation is managed through the raised flooring and free flowing ceiling return system which can eliminate almost 90% of HVAC distribution branch ductwork on the project.

What is Underfloor Air Distribution (UFAD)?

Conclusion: A Harmonious Future for Mass Timber

As the construction industry embraces more sustainable building practices, the combination of Underfloor Air Distribution and Raised Access Flooring with Mass Timber represents a forward-thinking solution. These systems improve energy efficiency, air quality, and flexibility while enhancing the performance and aesthetics of timber buildings. The potential for reducing energy consumption and minimizing the carbon footprint is particularly important in today’s quest for more sustainable architecture.

Mass timber, paired with UFAD and RAF, has the power to transform how we approach the design of modern buildings—creating flexible, sustainable, and healthy environments for occupants while advancing the use of renewable materials. With these systems working together, the future of construction is undoubtedly green, innovative, and efficient.

5

8" finished floor height accommodated interior zone diffusers (manually or automatically operated).

Two 5,000 CFM Air Towers were installed on each floor to optimize energy savings and create equipment redundancies.

A hydronic heating water system was designed and built as the heating source for the perimeter finned-tube heaters. The installed system utilizes two high-efficiency electric heat-pump boilers to generate heating water. These heat pumps are approximately 3.5 times more efficient than traditional electric strip heaters, and approximately 4 times more efficient than natural gas-fired boilers.

Outside air and restroom exhaust are served by a single dedicated outdoor air system (DOAS unit) with a total energy recovery wheel, and 14 tons of packaged DX air conditioning for pretreatment and dehumidification of the ventilation air.

The system relies on a continuous linear plenum to effectively cool and heat the perimeter of the building. UFAD dampers, placed every four feet along the plenum, deliver under-floor cooling air to meet cooling loads. Continuous hydronic finned-tube heating elements located within the plenum provide efficient heating during the winter.

System Components

Mass timber already contributes to the building's sustainability through its low carbon footprint, and the integration of UFAD and RAF further enhances this by reducing the energy required for heating, cooling, and ventilation.

The UFAD system improves energy efficiency by harnessing natural convection, ensuring even airflow with reduced need for energy-intensive fans, offering an average of 20-30% more efficiency than traditional overhead HVAC systems.

The raised floor systems can support energy-efficient lighting, and electrical systems, and allow for integration of renewable energy systems like radiant cooling or heating.

Together, these elements combine to create a building with lower overall energy consumption, aligning with environmental goals such as reducing carbon emissions and lowering utility costs.

Enhanced Sustainability

Why Combine UFAD and RAF in Mass Timber Construction?

Acoustic Comfort

With UFAD, air is delivered at low velocities from the floor, reducing the likelihood of dust and pollutants circulating throughout the room. Additionally, the ability to control air distribution precisely allows for better indoor air quality, which is essential for occupant health and well-being.

Reduced allergens: By delivering air from the ground level, UFAD reduces the chances of allergens, dust, or contaminants being suspended in the air.

Localized cooling and heating: UFAD allows individual control over temperature zones, ensuring that occupants experience consistent and comfortable environmental conditions without the need for complex ductwork.

Improved Indoor Air Quality (IAQ)

The combination of mass timber and RAF can significantly improve the acoustics of a building. A RAF system can be installed above mass timber floor assemblies designed to absorb sound transmission through the floor, and reduce mechanical noise caused by traditional overhead ductwork. Additionally, the absence of overhead ducts or vents enhances the overall acoustic performance of the space.

An additional benefit of deploying a RAF/UFAD solution is that you can significantly reduce the amount of concrete and acoustic matting required due to the acoustic performance of the RAF system and air gap/plenum.

Objectives of this case study

The main objective of this initiative is to assess thermal and environmental performance of wood fibre insulation compared to traditional solutions, while highlighting the challenges linked to integrating wood fibre insulation in Québec construction practices.

In addition, the goal of this project was to show the multiple potential options of integrating wood materials in an educational public building in the interior of the same building, and the resulting benefits (reducing GHG, biophilia, using local manpower, quality learning spaces, etc.).

We hope that École des Cerisiers will be used as an example to highlight the technical performance of this type of insulation, difficulties encountered in the installation stage, solutions adopted and prospects they offer to the construction sector.