Projects We Love

Buildings We Love

The Exchange

kelowna, bc

Scroll to Read

In Kelowna, British Columbia’s evolving industrial north end, The Exchange stands as a forward-thinking demonstration of what’s possible when architectural ambition meets technical precision. Designed and developed by Faction Architecture and Faction Projects, the building blends mass timber with conventional materials in a hybrid system that highlights both structural performance and environmental responsibility.

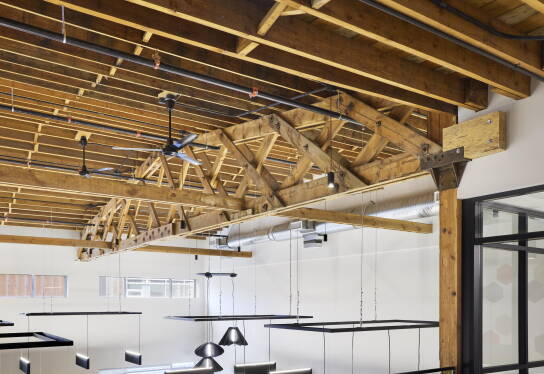

At the heart of the structural system is nail-laminated timber (NLT), used for both floor and roof assemblies. NLT is a mass timber product formed by mechanically fastening dimensional lumber together to create solid panels—an approach well-suited to exposed timber applications that value durability, texture, and straightforward fabrication. For this project, the team fabricated the panels in-house using locally sourced materials and trades. While this gave them greater control over cost and scheduling, it also introduced design and compliance challenges.

ARCHITECT:

Faction Architecture Inc.

STRUCTURAL ENGINEER:

RJC Engineers

DEVELOPER:

Faction Projects Inc.

CONSTRUCTION MANAGER:

Faction Construction

BUILDING CODE CONSULTANT:

GHL Consultants Ltd.

PHOTOS:

Courtesy of naturally:wood

All photos by Ed White Photographics, courtesy naturallywood.com

The Exchange also showcases a thoughtful approach to the building envelope, a key factor in achieving Step 3 of the BC Energy Step Code—the highest step currently applicable to non-residential buildings in the region. The high-performance envelope includes a combination of weathering steel and corrugated metal cladding, high-performance glass windows, semi-rigid exterior insulation, breathable weather barrier, plywood sheathing, lumber studs, batt insulation, gypsum board and a polyethylene vapour barrier. The light-frame wood walls contribute to envelope performance in two important ways: 1) wood has lower thermal conductivity than other materials, so thermal bridging is dramatically reduced, and 2) the stud wall configuration allowed for thicker insulation in the cavities between studs.

This integrated approach—combining exposed timber construction, envelope efficiency, and locally supported fabrication—enabled the project team to deliver a space that performs as well technically as it does aesthetically. And with over 90% of the leasable area spoken for at completion, it’s clear that tenants are responding to both the look and the logic of the building.

The Exchange sets a precedent for accessible mass timber construction in smaller markets, particularly in contexts where a streamlined fabrication process and strong design-control loop can help close the gap between sustainable ambition and budgetary constraints.

As Faction Projects continues work on the remaining phases of the development, The Exchange stands as both a technical prototype and a commercial success—proof that high-performance, low-carbon construction can be as practical as it is inspiring.

The team opted for a fluted NLT profile to enhance visual appeal and improve acoustic performance. Because the panel design differed from prescriptive norms, it required approval as an alternative solution under the BC Building Code. Extensive analysis was conducted to demonstrate compliance with fire-resistance, vibration, and load-bearing requirements. Informed by existing NLT fire test data, the design team minimized voids between laminations to enhance charring behaviour and performed physical load testing at Okanagan College to confirm strength and stiffness performance.

Complementing the NLT panels is a glulam post-and-beam system that forms the substructure, supported by concrete elevator and stair cores. Together, these elements support a program that includes retail and light industrial space at grade, with two to three storeys of open-plan office space above. A rooftop patio offers sweeping views, reinforcing the project’s appeal to creative businesses and environmentally conscious tenants.

Buildings We Love

UNB Head Hall Engineering Commons University of New Brunswick, Fredericton, NB

The new Engineering Commons at the University of New Brunswick's Head Hall is a model of integrated mass timber design, serving both as a structural solution and a pedagogical showcase. Designed by Murdock & Boyd Architects, with structural engineering by Eastern Designers & Company Ltd., this four-storey addition—including a basement—delivers a contemporary response to the university’s call for a collaborative, light-filled, and forward-looking academic space.

At the heart of the structure is a hybrid system that marries cast-in-place concrete with mass timber, specifically cross-laminated timber (CLT) and glue-laminated timber (glulam). The building's basement (Level B) and ground floor (Level C) are constructed with conventional reinforced concrete. These levels are supported by concrete columns and retaining walls, founded on either glacial till or steel pipe piles in areas adjacent to the two-storey basement of the existing structure. The concrete flat slab at the ground level provides a robust transfer system for the timber superstructure above.

Ultimately, the UNB Head Hall addition not only expands the functionality and visual identity of the Engineering Complex but also advances mass timber as a technically viable and code-compliant solution in institutional contexts. Through careful integration of structure, systems, and aesthetics, the project stands as a compelling case study in modern timber engineering.

The roof system includes a two-ply self-adhered modified bitumen membrane with tapered insulation to direct drainage. A prominent sloped skylight atop the atrium maximizes natural light penetration and highlights the rhythm of the glulam framing below.

A significant engineering challenge was addressed through an alternative solution under the National Building Code of Canada (2015), which typically requires non-combustible construction for this occupancy type. The design team, with RJ Bartlett Engineering, demonstrated that the mass timber elements could meet the required fire resistance ratings, flame spread, and smoke development thresholds through a combination of sprinkler protection, assembly detailing, and fire performance modeling.

The upper two floors (Levels D and E), along with the roof, are built entirely from CLT floor and roof panels supported on glulam beams and columns. The CLT floor panels are 245 mm thick and span up to 6.0 metres, with a 50 mm concrete topping slab and 25 mm rigid insulation for acoustic attenuation. The roof panels, measuring 197 mm thick, are constructed to the same span. The CLT panels are exposed on the underside, offering both structural performance and biophilic benefits to the interior environment.

A key detail of the project is the glulam-to-CLT and CLT-to-CLT connections. The beam-to-column assemblies utilize custom steel hardware, concealed where possible by wood blocking for both aesthetic continuity and fire protection. CLT diaphragms are interconnected using light gauge steel plates and fasteners, forming a continuous load path and providing lateral stability. Additional bracing is achieved through a proprietary system of steel rods and hollow structural sections (HSS), strategically connected via gusset plates.

ARCHITECT:

Murdock & Boyd Architects

STRUCTURAL ENGINEER:

Eastern Designers & Company Limited

MASS TIMBER SUPPLIER:

Nordic Structures

CONTRACTOR:

EllisDon Corporation

PHOTOS AND RENDERINGS:

Murdock & Boyd Architects

Projects We Love

Buildings We Love

The Exchange

kelowna, bc

All photos by Ed White Photographics, courtesy naturallywood.com

This integrated approach—combining exposed timber construction, envelope efficiency, and locally supported fabrication—enabled the project team to deliver a space that performs as well technically as it does aesthetically. And with over 90% of the leasable area spoken for at completion, it’s clear that tenants are responding to both the look and the logic of the building.

The Exchange sets a precedent for accessible mass timber construction in smaller markets, particularly in contexts where a streamlined fabrication process and strong design-control loop can help close the gap between sustainable ambition and budgetary constraints.

As Faction Projects continues work on the remaining phases of the development, The Exchange stands as both a technical prototype and a commercial success—proof that high-performance, low-carbon construction can be as practical as it is inspiring.

The Exchange also showcases a thoughtful approach to the building envelope, a key factor in achieving Step 3 of the BC Energy Step Code—the highest step currently applicable to non-residential buildings in the region. The high-performance envelope includes a combination of weathering steel and corrugated metal cladding, high-performance glass windows, semi-rigid exterior insulation, breathable weather barrier, plywood sheathing, lumber studs, batt insulation, gypsum board and a polyethylene vapour barrier. The light-frame wood walls contribute to envelope performance in two important ways: 1) wood has lower thermal conductivity than other materials, so thermal bridging is dramatically reduced, and 2) the stud wall configuration allowed for thicker insulation in the cavities between studs.

The team opted for a fluted NLT profile to enhance visual appeal and improve acoustic performance. Because the panel design differed from prescriptive norms, it required approval as an alternative solution under the BC Building Code. Extensive analysis was conducted to demonstrate compliance with fire-resistance, vibration, and load-bearing requirements. Informed by existing NLT fire test data, the design team minimized voids between laminations to enhance charring behaviour and performed physical load testing at Okanagan College to confirm strength and stiffness performance.

Complementing the NLT panels is a glulam post-and-beam system that forms the substructure, supported by concrete elevator and stair cores. Together, these elements support a program that includes retail and light industrial space at grade, with two to three storeys of open-plan office space above. A rooftop patio offers sweeping views, reinforcing the project’s appeal to creative businesses and environmentally conscious tenants.

The project team successfully advocated for a mass timber design, emphasizing its environmental and aesthetic benefits. The result is a four-storey hybrid structure of mass timber and steel, featuring three levels of cross-laminated timber (CLT) over a concrete parking podium. Exposed timber enhances both the aesthetics and user experience.

Construction took place on a tight urban site, necessitating efficient space management. Prefabricated CLT panels and pre-finished glulam beams streamlined the assembly process, saving time and resources. Many components arrived ready for installation, reducing on-site storage needs.

AFV's new home, described as a “new and improved Francophone centre,” houses a 165-seat theatre, classrooms, an art gallery, artist studios, a demonstration kitchen, a library with digital media resources, a public café, and a rooftop terrace for community events. The central atrium, flooded with natural light, helps visitors navigate the building and connects various activities.

ARCHITECT:

Faction Architecture Inc.

STRUCTURAL ENGINEER:

RJC Engineers

DEVELOPER:

Faction Projects Inc.

CONSTRUCTION MANAGER:

Faction Construction

BUILDING CODE CONSULTANT:

GHL Consultants Ltd.

PHOTOS:

Courtesy of naturally:wood

In Kelowna, British Columbia’s evolving industrial north end, The Exchange stands as a forward-thinking demonstration of what’s possible when architectural ambition meets technical precision. Designed and developed by Faction Architecture and Faction Projects, the building blends mass timber with conventional materials in a hybrid system that highlights both structural performance and environmental responsibility.

At the heart of the structural system is nail-laminated timber (NLT), used for both floor and roof assemblies. NLT is a mass timber product formed by mechanically fastening dimensional lumber together to create solid panels—an approach well-suited to exposed timber applications that value durability, texture, and straightforward fabrication. For this project, the team fabricated the panels in-house using locally sourced materials and trades. While this gave them greater control over cost and scheduling, it also introduced design and compliance challenges.

Buildings We Love

UNB Head Hall Engineering Commons University of New Brunswick, Fredericton, NB

ARCHITECT:

Murdock & Boyd Architects

STRUCTURAL ENGINEER:

Eastern Designers & Company Limited

MASS TIMBER SUPPLIER:

Nordic Structures

CONTRACTOR:

EllisDon Corporation

PHOTOS AND RENDERINGS:

Murdock & Boyd Architects

Ultimately, the UNB Head Hall addition not only expands the functionality and visual identity of the Engineering Complex but also advances mass timber as a technically viable and code-compliant solution in institutional contexts. Through careful integration of structure, systems, and aesthetics, the project stands as a compelling case study in modern timber engineering.

The roof system includes a two-ply self-adhered modified bitumen membrane with tapered insulation to direct drainage. A prominent sloped skylight atop the atrium maximizes natural light penetration and highlights the rhythm of the glulam framing below.

A significant engineering challenge was addressed through an alternative solution under the National Building Code of Canada (2015), which typically requires non-combustible construction for this occupancy type. The design team, with RJ Bartlett Engineering, demonstrated that the mass timber elements could meet the required fire resistance ratings, flame spread, and smoke development thresholds through a combination of sprinkler protection, assembly detailing, and fire performance modeling.

The upper two floors (Levels D and E), along with the roof, are built entirely from CLT floor and roof panels supported on glulam beams and columns. The CLT floor panels are 245 mm thick and span up to 6.0 metres, with a 50 mm concrete topping slab and 25 mm rigid insulation for acoustic attenuation. The roof panels, measuring 197 mm thick, are constructed to the same span. The CLT panels are exposed on the underside, offering both structural performance and biophilic benefits to the interior environment.

A key detail of the project is the glulam-to-CLT and CLT-to-CLT connections. The beam-to-column assemblies utilize custom steel hardware, concealed where possible by wood blocking for both aesthetic continuity and fire protection. CLT diaphragms are interconnected using light gauge steel plates and fasteners, forming a continuous load path and providing lateral stability. Additional bracing is achieved through a proprietary system of steel rods and hollow structural sections (HSS), strategically connected via gusset plates.

The new Engineering Commons at the University of New Brunswick's Head Hall is a model of integrated mass timber design, serving both as a structural solution and a pedagogical showcase. Designed by Murdock & Boyd Architects, with structural engineering by Eastern Designers & Company Ltd., this four-storey addition—including a basement—delivers a contemporary response to the university’s call for a collaborative, light-filled, and forward-looking academic space.

At the heart of the structure is a hybrid system that marries cast-in-place concrete with mass timber, specifically cross-laminated timber (CLT) and glue-laminated timber (glulam). The building's basement (Level B) and ground floor (Level C) are constructed with conventional reinforced concrete. These levels are supported by concrete columns and retaining walls, founded on either glacial till or steel pipe piles in areas adjacent to the two-storey basement of the existing structure. The concrete flat slab at the ground level provides a robust transfer system for the timber superstructure above.