The number of economic shocks that we have weathered in recent years is simply incredible. Navigating through each one has been arduous, to say the least – but there is another, more troubling aspect of this constantly changing landscape that deserves our attention. As the rate of change increases, and the future becomes even more unpredictable, companies may defer committing to a long-term strategy, especially one that involves significant capital investment or exposure to new products and methods. In times of uncertainty, our natural inclination is to hold our position, and yet the current housing crisis is pushing us to find new and innovative ways to increase our housing stock.

One way to move your business forward without ‘betting the farm’ is to ignore the volatility, focus on what you can control, and learn your craft.

Learning your craft means developing and enhancing the fundamental skills and systems required to be a strong operator in this highly competitive market. This is the nuts and bolts of offsite construction, focused on how we design, manufacture, and assemble homes, not our marketing strategy, capital raise, or the technology we employ. It’s a hands-on endeavour. Experiential, not transactional. Part of a long journey towards operational excellence, not simply a race to be first to market.

This may sound boring and overly simplistic but overlook it at your peril. Gerry McCaughey was one of the world’s foremost authorities on off-site construction, and he would often state that North America doesn’t have a labour shortage issue, it has an efficiency issue. I wholeheartedly agree with Gerry. Respectfully, I might even take it one step further. Our efficiency issue in the field is obvious, but it’s also prevalent in many of our prefabrication plants, so I would suggest that our problem runs deeper. Beyond efficiency, we have a capability issue.

We’re not capable? No, not exactly. We just haven’t reached our full potential – at least, not industry-wide. We know we need the efficiency that comes from manufacturing prefabricated elements — we’re just not that good at it yet. Why? Because we simply need more time. Time to learn, practice, develop, and evolve. The key is to commit time and resources to these specific activities, and be deliberate, because they won’t happen on their own.

The current pressure to increase our housing stock has some companies overlooking the basics, with their sights fixed squarely on the endgame. Yes, it’s imperative that we never lose sight of the goal, but we also need to acknowledge the fact that, as an industry, we are truly just beginning this prefabrication journey and would be well-served to focus our efforts on developing and refining fundamental skills, techniques, and systems. Real progress takes time — and we don’t have to look far to see how this plays out in other industries.

Take the automotive sector and world-class European homebuilders, for example. They were not created overnight. They evolved. Three to five generations of evolution, hard work, critical learning, and skill development have produced a depth of expertise and experience that cannot be purchased or copied. Their other strength, which is equally important, is that they are engineering and manufacturing companies first. Their products may be the automobiles and residential homes, but if they were making any other industrialized product, their mindset and approach would be the same. We’ll circle back to mindset in a moment.

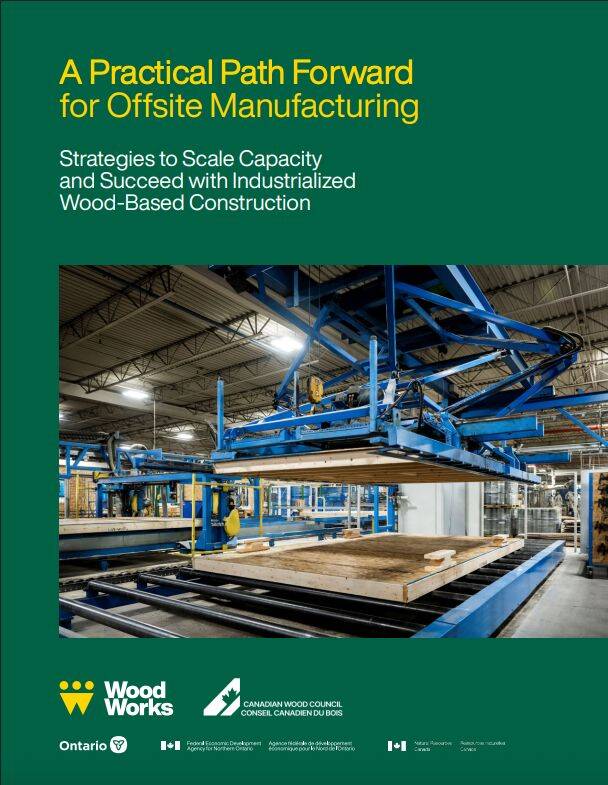

FEATURE

Learn Your Craft – Offsite Manufacturing

Scroll to Read

Mike Schmidt, President, Auto Construct Incorporated

A Tool & Die Maker with a master’s degree in business administration, Mike understands manufacturing from the ground up. He spent his formative years as an executive in the automotive industry, working for world-class, multinational corporations such as Magna International and ArcelorMittal.

In 2017, Mike established Auto Construct Incorporated (ACI), a management consulting firm, to accelerate the industrialization of residential construction. Specializing in the conversion from stick-built to offsite construction, Mike has led and facilitated the growth of several companies to become dominant players in their respective fields.

ACI provides education, guidance, and implementation support in the areas of business development, manufacturing systems, technology selection, and factory start-ups. ACI serves a broad range of land developers, construction firms, homebuilders, and manufacturing companies throughout Canada and the United States.

The most obvious benefit is basic competency and enhanced performance. This applies to start-ups trying to make the cut and to mature companies that want to improve their game and strengthen their competitive position.

This may seem counter-intuitive, but the next benefit has to do with technology. Technical advancements such as automation, robotics, generative design, and artificial intelligence are undeniably powerful, but they cannot be fully leveraged without a strong technical foundation. In the same way that a professional athlete can edge out the competition by using superior equipment, advanced technology enhances our existing ability; it does not replace core competency. So, as you improve your bench strength, you’re actually creating a springboard for the benefits that advanced technology offers.

Finally, a commitment to learning your craft is a mindset. It’s a religion. The pursuit of operational excellence will create a culture of continuous improvement that will alter the way your business thinks and behaves. After a period of time, the habit is set, and it becomes a cornerstone of your organizational culture. Now, as you deliberate on the next major step in the evolution of your business, you can rest assured that your team is already moving you in the right direction, creating a springboard for your next quantum leap.

Learning your craft isn’t complicated – it’s about getting the simple things right. How can you minimize the number of components in a rough-sized opening for a window frame? What type of corner connections are easiest for onsite installation? Are you ready for multi-wall designs that make full use of your framing and sheathing stations? Have you eliminated balloon framing for tall walls? There are hundreds of small decisions – process changes, product refinements, and assembly techniques – that, when mastered, can transform a prefab builder into a world-class manufacturer.

So, why emphasize the back-to-basics initiative if you’re already a player in this industry? Well, there are three major benefits associated with this approach, and a couple of them may surprise you.

The number of economic shocks that we have weathered in recent years is simply incredible. Navigating through each one has been arduous, to say the least – but there is another, more troubling aspect of this constantly changing landscape that deserves our attention. As the rate of change increases, and the future becomes even more unpredictable, companies may defer committing to a long-term strategy, especially one that involves significant capital investment or exposure to new products and methods. In times of uncertainty, our natural inclination is to hold our position, and yet the current housing crisis is pushing us to find new and innovative ways to increase our housing stock.

One way to move your business forward without ‘betting the farm’ is to ignore the volatility, focus on what you can control, and learn your craft.

Learning your craft means developing and enhancing the fundamental skills and systems required to be a strong operator in this highly competitive market. This is the nuts and bolts of offsite construction, focused on how we design, manufacture, and assemble homes, not our marketing strategy, capital raise, or the technology we employ. It’s a hands-on endeavour. Experiential, not transactional. Part of a long journey towards operational excellence, not simply a race to be first to market.

This may sound boring and overly simplistic but overlook it at your peril. Gerry McCaughey was one of the world’s foremost authorities on off-site construction, and he would often state that North America doesn’t have a labour shortage issue, it has an efficiency issue. I wholeheartedly agree with Gerry. Respectfully, I might even take it one step further. Our efficiency issue in the field is obvious, but it’s also prevalent in many of our prefabrication plants, so I would suggest that our problem runs deeper. Beyond efficiency, we have a capability issue.

We’re not capable? No, not exactly. We just haven’t reached our full potential – at least, not industry-wide. We know we need the efficiency that comes from manufacturing prefabricated elements — we’re just not that good at it yet. Why? Because we simply need more time. Time to learn, practice, develop, and evolve. The key is to commit time and resources to these specific activities, and be deliberate, because they won’t happen on their own.

The current pressure to increase our housing stock has some companies overlooking the basics, with their sights fixed squarely on the endgame. Yes, it’s imperative that we never lose sight of the goal, but we also need to acknowledge the fact that, as an industry, we are truly just beginning this prefabrication journey and would be well-served to focus our efforts on developing and refining fundamental skills, techniques, and systems. Real progress takes time — and we don’t have to look far to see how this plays out in other industries.

Take the automotive sector and world-class European homebuilders, for example. They were not created overnight. They evolved. Three to five generations of evolution, hard work, critical learning, and skill development have produced a depth of expertise and experience that cannot be purchased or copied. Their other strength, which is equally important, is that they are engineering and manufacturing companies first. Their products may be the automobiles and residential homes, but if they were making any other industrialized product, their mindset and approach would be the same. We’ll circle back to mindset in a moment.

FEATURE

Learn Your Craft – Offsite Manufacturing

The most obvious benefit is basic competency and enhanced performance. This applies to start-ups trying to make the cut and to mature companies that want to improve their game and strengthen their competitive position.

This may seem counter-intuitive, but the next benefit has to do with technology. Technical advancements such as automation, robotics, generative design, and artificial intelligence are undeniably powerful, but they cannot be fully leveraged without a strong technical foundation. In the same way that a professional athlete can edge out the competition by using superior equipment, advanced technology enhances our existing ability; it does not replace core competency. So, as you improve your bench strength, you’re actually creating a springboard for the benefits that advanced technology offers.

Finally, a commitment to learning your craft is a mindset. It’s a religion. The pursuit of operational excellence will create a culture of continuous improvement that will alter the way your business thinks and behaves. After a period of time, the habit is set, and it becomes a cornerstone of your organizational culture. Now, as you deliberate on the next major step in the evolution of your business, you can rest assured that your team is already moving you in the right direction, creating a springboard for your next quantum leap.

Learning your craft isn’t complicated – it’s about getting the simple things right. How can you minimize the number of components in a rough-sized opening for a window frame? What type of corner connections are easiest for onsite installation? Are you ready for multi-wall designs that make full use of your framing and sheathing stations? Have you eliminated balloon framing for tall walls? There are hundreds of small decisions – process changes, product refinements, and assembly techniques – that, when mastered, can transform a prefab builder into a world-class manufacturer.

So, why emphasize the back-to-basics initiative if you’re already a player in this industry? Well, there are three major benefits associated with this approach, and a couple of them may surprise you.

Mike Schmidt, President, Auto Construct Incorporated

A Tool & Die Maker with a master’s degree in business administration, Mike understands manufacturing from the ground up. He spent his formative years as an executive in the automotive industry, working for world-class, multinational corporations such as Magna International and ArcelorMittal.

In 2017, Mike established Auto Construct Incorporated (ACI), a management consulting firm, to accelerate the industrialization of residential construction. Specializing in the conversion from stick-built to offsite construction, Mike has led and facilitated the growth of several companies to become dominant players in their respective fields.

ACI provides education, guidance, and implementation support in the areas of business development, manufacturing systems, technology selection, and factory start-ups. ACI serves a broad range of land developers, construction firms, homebuilders, and manufacturing companies throughout Canada and the United States.