FEATURE

A GROWING ROLE FOR WOOD IN CONSTRUCTION

Scroll to Read

Wood is a renewable, local material with a low carbon footprint, making it a key ally in the fight against climate change. In addition to its environmental performance, wood facilitates prefabrication, simplifies foundation and finishing elements and provides better thermal insulation.

How do trees sequester carbon?

Wood is one of the few building materials capable of storing carbon over its entire lifespan. Through the process of photosynthesis, trees absorb carbon dioxide (CO2) from the atmosphere and transform it into oxygen (O2). It then uses the carbon (C) in the CO2to form its material (wood), enabling it to grow. In general, it is estimated that 1 m3 of wood sequesters just under 1 tonne of CO2. Once mature, the tree grows at a slower rate and stores less carbon. After 75 to 120 years of life, trees will eventually die and decompose naturally, aided by fungi and/or insects, or sooner if burned in a forest fire.

In this way, much of the carbon accumulated during its life will be returned to the atmosphere in the form of CO2, thereby completing the forest carbon cycle. The harvested tree is replaced by a younger one, thus starting a new cycle of carbon sequestration cycle. By using wood as a building material, we delay the moment when this carbon is released or re-emitted into the atmosphere. Therefore, it is possible to extend forest carbon sequestration beyond the life of the tree by using it as a building material.

Why use wood in construction?

Materials used in the construction sector, such as steel and concrete, generate a significant amount of GHG emissions over their entire lifespan due to the extraction of raw materials, the manufacturing stage, their use and their end-of-life sequence. On the other hand, in addition to having a low carbon footprint, wood generates only a small amount of GHG emissions linked to the harvesting and manufacturing stage. Not only is it capable of storing carbon, but it does so for the entire life of the product.

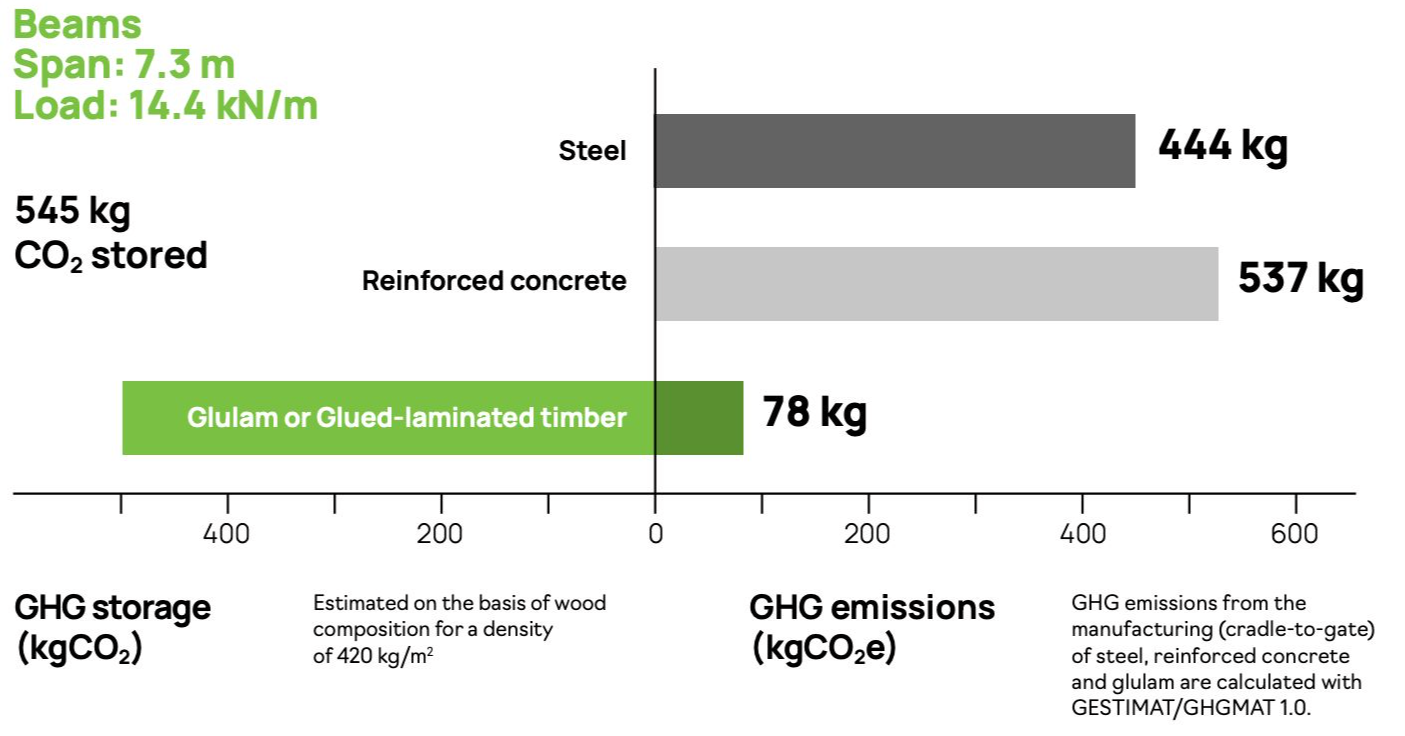

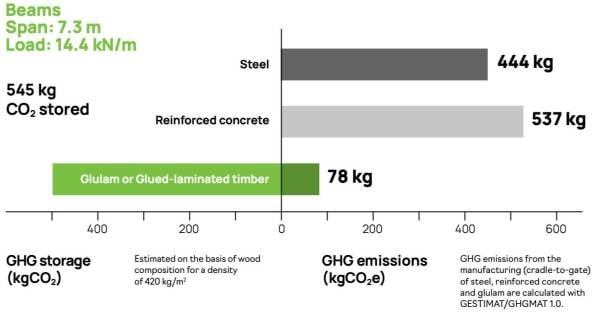

To provide a valid basis for comparison between the three materials (steel, concrete and wood), Cecobois used the GESTIMAT/GHGMAT tool to compare a single-support beam with a standard load case (14.4 kN/m) and a standard span (7.3 m). For a beam carrying the same load and span, glulam emits just 78 kgCO2e versus reinforced concrete and steel with 444 and 537 kgCO2e respectively, a reduction of over 80%. What’s more, this same wood beam will store 545 kgCO2 over its lifetime.

GHG emissions results for the manufacture of a beam, considering cross-laminated timber, reinforced concrete and steel scenarios.

The advantages of building with wood

Facilitates prefabrication

Prefabrication is a construction practice that enables several factory-built building components to be assembled directly on site. This practice offers many advantages, such as improved cost and time management, a safe working environment, higher productivity, higher quality, faster construction and reduced waste generation. Wood is a material that lends itself well to prefabrication because the factory allows the optimisation of cutting patterns. Moreover, material losses generated by cutting are more easily sorted and reintegrated into the production chain than if they had been generated on the construction site.

simplifies foundations and finishing elements

Wood building structures are considerably lighter than structures made of steel or concrete, and they can help make foundations less complex. This can be particularly advantageous in projects on sites with low load-bearing capacity or those requiring the addition of another storey to an existing building.

Because of their natural fire resistance, Glulam and CLT structures are often left exposed, requiring fewer finishing elements than other structural systems. These structural systems make the building seem more welcoming, providing added value.

provides superior thermal insulation

In addition to the importance of embodied carbon, the energy efficiency of buildings remains a key consideration in the 2030 PGE. The plan urges the reduction of energy consumption in buildings. That said, using less energy requires better insulation. As wood’s thermal resistance is 500 times greater than that of steel and seven times greater than that of concrete, its use in structural products reduces thermal bridges and makes it easier to install effective thermal insulation. Reducing the transfer of heat through building walls reduces energy consumption for heating and ventilation while increasing user comfort.

This natural property of wood is also featured in the development of various bio-sourced insulating panels.

Click here to access the special 'Decarbonization' edition of Cecbois' quarterly journal

The advantages of building with wood

How do trees sequester carbon?

Wood is one of the few building materials capable of storing carbon over its entire lifespan. Through the process of photosynthesis, trees absorb carbon dioxide (CO2) from the atmosphere and transform it into oxygen (O2). It then uses the carbon (C) in the CO2to form its material (wood), enabling it to grow. In general, it is estimated that 1 m3 of wood sequesters just under 1 tonne of CO2. Once mature, the tree grows at a slower rate and stores less carbon. After 75 to 120 years of life, trees will eventually die and decompose naturally, aided by fungi and/or insects, or sooner if burned in a forest fire.

In this way, much of the carbon accumulated during its life will be returned to the atmosphere in the form of CO2, thereby completing the forest carbon cycle. The harvested tree is replaced by a younger one, thus starting a new cycle of carbon sequestration cycle. By using wood as a building material, we delay the moment when this carbon is released or re-emitted into the atmosphere. Therefore, it is possible to extend forest carbon sequestration beyond the life of the tree by using it as a building material.

FEATURE

A GROWING ROLE FOR WOOD IN CONSTRUCTION

Why use wood in construction?

Materials used in the construction sector, such as steel and concrete, generate a significant amount of GHG emissions over their entire lifespan due to the extraction of raw materials, the manufacturing stage, their use and their end-of-life sequence. On the other hand, in addition to having a low carbon footprint, wood generates only a small amount of GHG emissions linked to the harvesting and manufacturing stage. Not only is it capable of storing carbon, but it does so for the entire life of the product.

To provide a valid basis for comparison between the three materials (steel, concrete and wood), Cecobois used the GESTIMAT/GHGMAT tool to compare a single-support beam with a standard load case (14.4 kN/m) and a standard span (7.3 m). For a beam carrying the same load and span, glulam emits just 78 kgCO2e versus reinforced concrete and steel with 444 and 537 kgCO2e respectively, a reduction of over 80%. What’s more, this same wood beam will store 545 kgCO2 over its lifetime.

GHG emissions results for the manufacture of a beam, considering cross-laminated timber, reinforced concrete and steel scenarios.

Facilitates prefabrication

Prefabrication is a construction practice that enables several factory-built building components to be assembled directly on site. This practice offers many advantages, such as improved cost and time management, a safe working environment, higher productivity, higher quality, faster construction and reduced waste generation. Wood is a material that lends itself well to prefabrication because the factory allows the optimisation of cutting patterns. Moreover, material losses generated by cutting are more easily sorted and reintegrated into the production chain than if they had been generated on the construction site.

simplifies foundations and finishing elements

Wood building structures are considerably lighter than structures made of steel or concrete, and they can help make foundations less complex. This can be particularly advantageous in projects on sites with low load-bearing capacity or those requiring the addition of another storey to an existing building.

Because of their natural fire resistance, Glulam and CLT structures are often left exposed, requiring fewer finishing elements than other structural systems. These structural systems make the building seem more welcoming, providing added value.

provides superior thermal insulation

In addition to the importance of embodied carbon, the energy efficiency of buildings remains a key consideration in the 2030 PGE. The plan urges the reduction of energy consumption in buildings. That said, using less energy requires better insulation. As wood’s thermal resistance is 500 times greater than that of steel and seven times greater than that of concrete, its use in structural products reduces thermal bridges and makes it easier to install effective thermal insulation. Reducing the transfer of heat through building walls reduces energy consumption for heating and ventilation while increasing user comfort.

This natural property of wood is also featured in the development of various bio-sourced insulating panels.

Click here to access the special 'Decarbonization' edition of Cecbois' quarterly journal

Wood is a renewable, local material with a low carbon footprint, making it a key ally in the fight against climate change. In addition to its environmental performance, wood facilitates prefabrication, simplifies foundation and finishing elements and provides better thermal insulation.