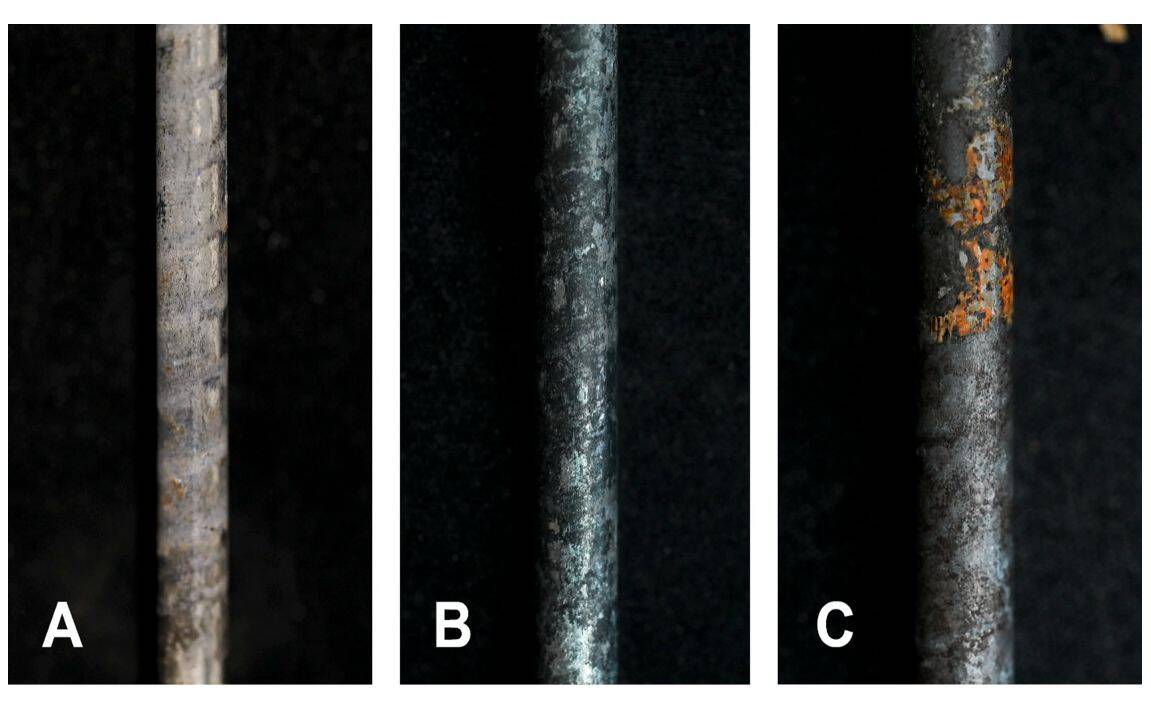

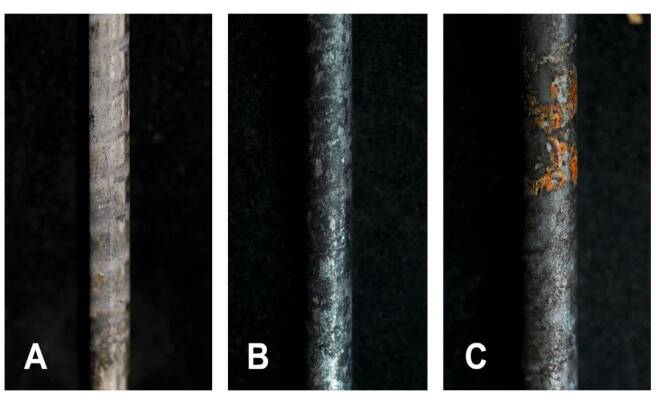

Figure 2. Images of (A) white rust, (B) black rust, and (C) red rust formed on mass timber screws tested by MTC Solutions for corrosion performance in SPF and D. Fir specimens in late 2024

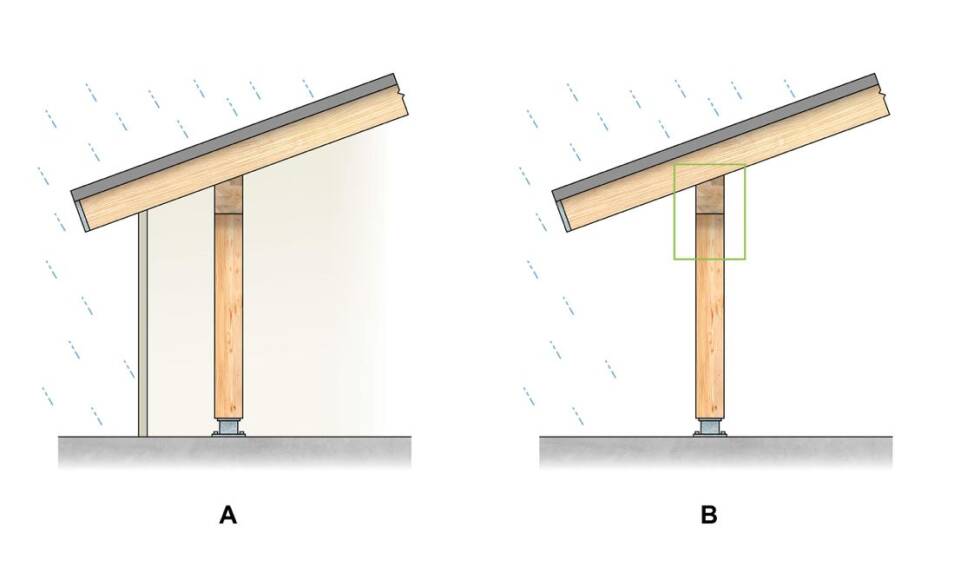

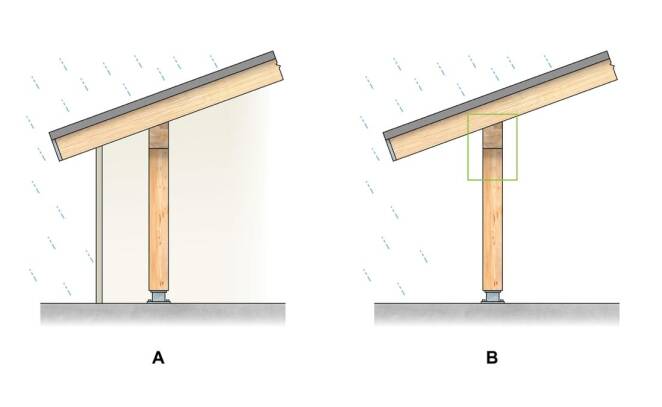

Figure 1. Common dry service environments

Additional Considerations for Wet Service Conditions

Connector material is only one aspect of connection design, accommodate wood swelling and shrinkage due to fluctuating moisture conditions to prevent excessive perpendicular-to-grain tension in wood. For example, use multiple narrow steel side plates rather than one wide plate. Wood connections exposed to moisture should promote shedding of water and prevent pooling. Understanding the potential movements of wood members when changing moisture content is critical to successful connection behaviour.

Choosing the right fasteners means accounting for service conditions and corrosion risks. By following best practices, you can ensure durable, high-performance mass timber connections. Contact MTC Technical Support Team for fastener recommendations tailored to your mass timber project’s environment—or for any other questions you might have!

Corrosion can weaken fasteners in mass timber connections over time, but with the right choices, you can protect your build. In this article, we’ll share expert tips to prevent corrosion and ensure lasting, reliable structures. To effectively combat corrosion, it’s crucial to first evaluate the conditions your fasteners will face and then choose the right materials and methods to protect them.

For dry service conditions, MTC Solutions provides carbon steel fasteners with regular corrosion resistance:

Case-hardened partially and fully threaded self-tapping screws (STSs)

Case-hardened self-drilling dowels

Wet Service Conditions

If a wood connection is expected to experience an MC greater than 19% during its service life, it falls into the “wet” service category. This significantly increases the risk of corrosion, impacting fastener durability and longevity.

Common wet service conditions include:

Exterior connections exposed to precipitation

Sheltered connections permanently exposed to outdoor air in regions with prolonged high RH (e.g., Olympia, WA)

Indoor spaces with high RH levels (e.g., indoor pools and greenhouses)

Typical dry service environments include:

Most indoor or enclosed structures (Figure 1A)

Most exterior structures where the wood is sheltered from precipitation (Figure 1B)

Dry Service Conditions

In both the U.S. and Canada, a dry service environment for wood connections means the timber’s MC is not expected to exceed 19% at any time throughout its service life. Canada goes a step further by requiring climatic conditions (i.e., temperature and relative humidity (RH)) that ensure the average equilibrium MC will remain below 15% on average over a year.

Why electroplated carbon steel screws shouldn’t be used in wet service conditions:

The electroplated zinc coating on carbon steel screws isn’t thick enough to protect against galvanic corrosion over the design life of the structure.

Carbon steel screws, with a core hardness greater than 360 HV, are susceptible to hydrogen embrittlement (HE) in wet conditions. Learn more from our articles on internal and environmental HE.

Why hot-dip galvanizing (HDG) isn’t used for corrosion protection in STSs:

HE risks: STSs are made with high-strength steel, making them unable to safely complete the acid pickling process needed for HDG without the risk of internal HE.

Exposure to high temperatures: As case-hardened steel fasteners, STSs cannot survive the high temperatures experienced during HDG without adverse effects on their mechanical properties.

Thread precision issues: Thick HDG coatings (typically 43–86 microns, per the American Galvanizers Association) dull the cutting surfaces of STSs, affecting their self-tapping ability.

Seating challenges: Thick HDG coatings can interfere with proper driver bit engagement in the screw head.

Higher torque: The rough surface texture of HDG coatings increases drive-in torque, which can increase user fatigue and prevent STSs from being fully installed.

For wet service conditions, we recommend fasteners with enhanced corrosion resistance, such as:

A2 Ecofast and A2 SK stainless steel fasteners—ideal for typical wet environments (contact our Technical Support Team for large orders)

A4 stainless steel fasteners—best for extreme corrosive conditions like those involving saltwater, aggressive chemicals, pressure-treated lumber, or submerged wood members (custom orders only; contact our Technical Support Team for assistance)

II. Material Selection & Compatibility

Choose the right fastener for its intended function and corrosion resistance. Use stainless steel for pressure-treated timber, taking advantage of its superior corrosion resistance without a damage-prone coating.

For wet service conditions, prevent galvanic corrosion by avoiding contact between electrochemically dissimilar metals (e.g., galvanized fasteners and stainless steel plates). Opt for materials with similar electrochemical properties or, when necessary, isolate dissimilar metals with plastic washers.

Zinc-plated fasteners may develop white and black rust, which is typically cosmetic. However, red rust, which generally forms when the zinc coating is compromised, indicates steel corrosion, signaling inappropriate fastener selection and potential connection failure. In such cases, it’s imperative to replace fasteners with appropriately designed corrosion-resistant alternatives.

Photo: StructureCraft

Photo: Stephane Groleau

I. Corrosion Risk Evaluation

When selecting fasteners for mass timber projects, understanding service conditions conducive to corrosion—such as wood with high moisture content—is crucial. These factors directly impact fastener durability, making them a top priority for designers to consider.

The first step in designing mass timber connections is understanding the environment your structure will face. Will the connection remain indoors in a dry, conditioned space, or will it be directly exposed to water or high levels of humidity for prolonged periods?

Assessing the anticipated moisture content (MC) of the wood in service is essential. It determines whether carbon steel or stainless steel is the right material for your fasteners, as each offers varying levels of corrosion resistance. Additional factors to consider are the potential for exposure to moisture combined with salt (e.g., think pedestrian bridges), and pollutants (e.g., fertilizers, chlorides, and sulfates). Another often-forgotten factor is the wood itself, some species, like yellow, red, and Alaskan cedars, are more acidic and may increase corrosion risks.

I. Corrosion Risk Evaluation

When selecting fasteners for mass timber projects, understanding service conditions conducive to corrosion—such as wood with high moisture content—is crucial. These factors directly impact fastener durability, making them a top priority for designers to consider.

The first step in designing mass timber connections is understanding the environment your structure will face. Will the connection remain indoors in a dry, conditioned space, or will it be directly exposed to water or high levels of humidity for prolonged periods?

Assessing the anticipated moisture content (MC) of the wood in service is essential. It determines whether carbon steel or stainless steel is the right material for your fasteners, as each offers varying levels of corrosion resistance. Additional factors to consider are the potential for exposure to moisture combined with salt (e.g., think pedestrian bridges), and pollutants (e.g., fertilizers, chlorides, and sulfates). Another often-forgotten factor is the wood itself, some species, like yellow, red, and Alaskan cedars, are more acidic and may increase corrosion risks.

Corrosion can weaken fasteners in mass timber connections over time, but with the right choices, you can protect your build. In this article, we’ll share expert tips to prevent corrosion and ensure lasting, reliable structures. To effectively combat corrosion, it’s crucial to first evaluate the conditions your fasteners will face and then choose the right materials and methods to protect them.

Typical dry service environments include:

Most indoor or enclosed structures (Figure 1A)

Most exterior structures where the wood is sheltered from precipitation (Figure 1B)

Dry Service Conditions

In both the U.S. and Canada, a dry service environment for wood connections means the timber’s MC is not expected to exceed 19% at any time throughout its service life. Canada goes a step further by requiring climatic conditions (i.e., temperature and relative humidity (RH)) that ensure the average equilibrium MC will remain below 15% on average over a year.

Figure 1. Common dry service environments

Why electroplated carbon steel screws shouldn’t be used in wet service conditions:

The electroplated zinc coating on carbon steel screws isn’t thick enough to protect against galvanic corrosion over the design life of the structure.

Carbon steel screws, with a core hardness greater than 360 HV, are susceptible to hydrogen embrittlement (HE) in wet conditions. Learn more from our articles on internal and environmental HE.

Why hot-dip galvanizing (HDG) isn’t used for corrosion protection in STSs:

HE risks: STSs are made with high-strength steel, making them unable to safely complete the acid pickling process needed for HDG without the risk of internal HE.

Exposure to high temperatures: As case-hardened steel fasteners, STSs cannot survive the high temperatures experienced during HDG without adverse effects on their mechanical properties.

Thread precision issues: Thick HDG coatings (typically 43–86 microns, per the American Galvanizers Association) dull the cutting surfaces of STSs, affecting their self-tapping ability.

Seating challenges: Thick HDG coatings can interfere with proper driver bit engagement in the screw head.

Higher torque: The rough surface texture of HDG coatings increases drive-in torque, which can increase user fatigue and prevent STSs from being fully installed.

For wet service conditions, we recommend fasteners with enhanced corrosion resistance, such as:

A2 Ecofast and A2 SK stainless steel fasteners—ideal for typical wet environments (contact our Technical Support Team for large orders)

A4 stainless steel fasteners—best for extreme corrosive conditions like those involving saltwater, aggressive chemicals, pressure-treated lumber, or submerged wood members (custom orders only; contact our Technical Support Team for assistance)

Figure 2. Images of (A) white rust, (B) black rust, and (C) red rust formed on mass timber screws tested by MTC Solutions for corrosion performance in SPF and D. Fir specimens in late 2024

Additional Considerations for Wet Service Conditions

Connector material is only one aspect of connection design, accommodate wood swelling and shrinkage due to fluctuating moisture conditions to prevent excessive perpendicular-to-grain tension in wood. For example, use multiple narrow steel side plates rather than one wide plate. Wood connections exposed to moisture should promote shedding of water and prevent pooling. Understanding the potential movements of wood members when changing moisture content is critical to successful connection behaviour.

Choosing the right fasteners means accounting for service conditions and corrosion risks. By following best practices, you can ensure durable, high-performance mass timber connections. Contact MTC Technical Support Team for fastener recommendations tailored to your mass timber project’s environment—or for any other questions you might have!

For dry service conditions, MTC Solutions provides carbon steel fasteners with regular corrosion resistance:

Case-hardened partially and fully threaded self-tapping screws (STSs)

Case-hardened self-drilling dowels

Wet Service Conditions

If a wood connection is expected to experience an MC greater than 19% during its service life, it falls into the “wet” service category. This significantly increases the risk of corrosion, impacting fastener durability and longevity.

Common wet service conditions include:

Exterior connections exposed to precipitation

Sheltered connections permanently exposed to outdoor air in regions with prolonged high RH (e.g., Olympia, WA)

Indoor spaces with high RH levels (e.g., indoor pools and greenhouses)

II. Material Selection & Compatibility

Choose the right fastener for its intended function and corrosion resistance. Use stainless steel for pressure-treated timber, taking advantage of its superior corrosion resistance without a damage-prone coating.

For wet service conditions, prevent galvanic corrosion by avoiding contact between electrochemically dissimilar metals (e.g., galvanized fasteners and stainless steel plates). Opt for materials with similar electrochemical properties or, when necessary, isolate dissimilar metals with plastic washers.

Zinc-plated fasteners may develop white and black rust, which is typically cosmetic. However, red rust, which generally forms when the zinc coating is compromised, indicates steel corrosion, signaling inappropriate fastener selection and potential connection failure. In such cases, it’s imperative to replace fasteners with appropriately designed corrosion-resistant alternatives.