Continuous CLT panels that run past demising walls can allow sound to travel laterally through the wood between suites, compromising code-required acoustic separation. Our research is focused on overcoming that challenge so projects can keep the mass timber visible – without losing control of noise or cost.

Mass timber has a powerful effect the moment someone walks into a space with exposed wood ceilings. After visiting hundreds of units over the years, that impression is unmistakable: standing in a living room with exposed CLT ceilings feels different. It borrows some of the calm of a wood cabin, even while in a busy multi-family building. Internationally, that impression has been reflected in the market – mass timber residential buildings are often positioned as higher-end and can command premium rents or sale prices. In Canada, however, mass timber has frequently been associated with affordable housing, in part because early adoption was driven by public funding aimed at innovative construction.

Well before residents experience that warm timber interior, design teams are making decisions that determine whether those ceilings can stay exposed or will disappear behind drywall. Where teams are less familiar with mass timber acoustics, managing acoustic risk with exposed CLT ceilings may warrant conservative measures: cutting CLT at every demising line, adding dropped nano-CLT ceilings, and other generous contingencies. Those strategies can protect performance, but they can also erode budgets to the point where the mass timber is value-engineered out entirely.

The core issue is that when CLT panels are continuous and exposed, design teams must consider not only the direct sound transmission through the floor/ceiling and wall assemblies, but also indirect (“flanking”) transmission through the ceiling-to-ceiling path via the continuous CLT between adjacent suites. Understanding – and controlling – that path is at the heart of this research.

FEATURE

New Acoustic Design Guidance and Research for Mass Timber Construction

Scroll to Read

Where and When to Find Results

The project has moved beyond concept. Most of the funding is secured, partners are confirmed, and the rig is underway. Testing is scheduled to begin in spring 2026 and conclude by the end of 2026. Once the core matrix is complete, we will release the database for open industry use.

The deliverable will not be a dense report that requires translation. Instead, we will provide a design-ready database that links clear test descriptions to the ceiling-to-ceiling path’s contribution to ASTC. For readers who want more depth, we will also outline how the design ratings were derived from the Kᵢⱼ measurements.

Tailor-Made Results for the Design Community

This initiative is education-first, with the wood design community squarely in mind. If there is a floor or roof topping you specify regularly—wet or dry—or an underlayment you rely on, we encourage you to connect with us (email: sedwards@hgcacoustics.com). Likewise, sharing the ASTC and AIIC targets you are seeing by building type will help us prioritize the test matrix and present results in formats that can be used directly in practice.

As testing progresses, we will keep the community informed. The intent is simple: to help teams keep the wood exposed, keep projects on budget, and keep acoustic performance where it needs to be.

Field Data that Shifted Our Understanding

Early lab testing and theory suggested that the ceiling-to-ceiling flanking path through continuous 5-ply CLT across a demising wall would limit performance to roughly ASTC-43 to ASTC-44, which is below code requirements across North America. Under those assumptions, acoustical consultants had little choice but to recommend cutting CLT panels at demising lines or installing dropped ceilings to achieve compliance.

Recent field testing across multiple buildings and configurations has shown that this picture is incomplete. Real projects rarely consist of bare CLT alone. Floor toppings, bulkheads, and adjacent construction all influence the ceiling-to-ceiling path – often in beneficial ways that were not captured in earlier lab work.

From those field investigations, several practical lessons have emerged for current projects:

Heavy toppings help. A heavyweight topping (e.g., concrete or gypsum-concrete) over an isolation layer on top of the CLT can significantly reduce ceiling-to-ceiling flanking, with measured performances in the ASTC-50+ range.

Dry toppings can work. A dry topping (e.g., plywood) over isolation material offers some reduction in ceiling flanking, although not as much as a wet topping. When combined with bulkheads on at least one side of the demising wall, ceiling-to-ceiling flanking can still land in the vicinity of ASTC-50 or higher.

More isolation isn’t always better. As the thickness of the isolation material increases, the topping’s ability to reduce flanking can diminish. With thicker isolation layers, performance can drift back toward the original ASTC-43 to 44 range.

Plan layouts to work with the structure. Higher acoustic targets can be met with continuous CLT by aligning unit layouts so that spaces with dropped ceilings or substantial bulkheads (e.g., kitchens and bathrooms) are mirrored across demising walls at the continuous-panel locations.

For each configuration we’ll measure the vibration reduction index Kᵢⱼ for the ceiling-to-ceiling route (per ISO 10848) and feed it into ISO 12354 to quantify that path’s contribution to ASTC. We’ll also run full ASTC tests of the demising wall (inclusive of ceiling-to-ceiling flanking) and collect ASTC, AIIC and walking-vibration data of the demising floor/ceiling (i.e., measuring up/down) so the acoustics and structural narratives line up.

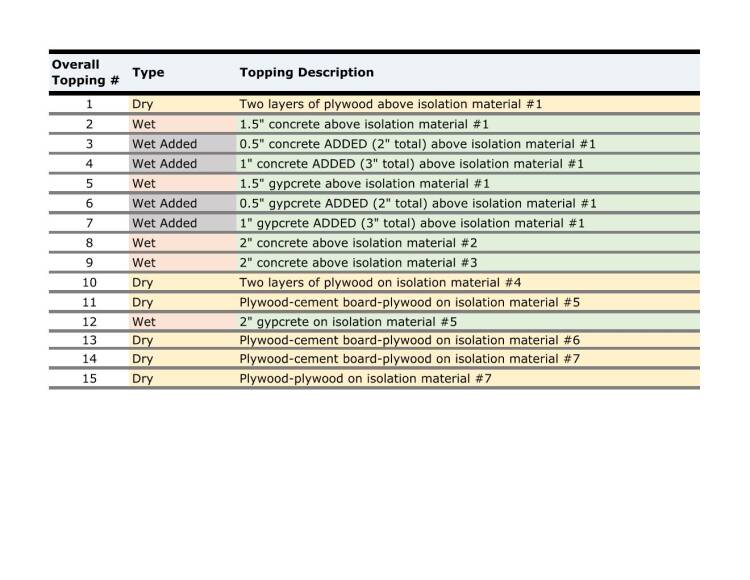

On toppings, the matrix is deliberately broad. We’ll test wet systems (concrete and gypsum-concrete at multiple thicknesses) and dry systems (plywood, cement board, proprietary materials), paired with underlayments across a range of thicknesses and dynamic stiffnesses. The sequencing is designed so we can compare like with like, and we’re managing curing/drying carefully so the numbers reflect the behaviour that designers will actually see after stabilization rather than just “day one in the lab.”

Different floor toppings (wet and dry systems)

Wall loading conditions

The effects of adjacent CLT (e.g., corridor panels)

The influence of modal resonances (e.g., furnished vs. unfurnished)

Bulkheads of varying sizes and configurations

What Are We Testing?

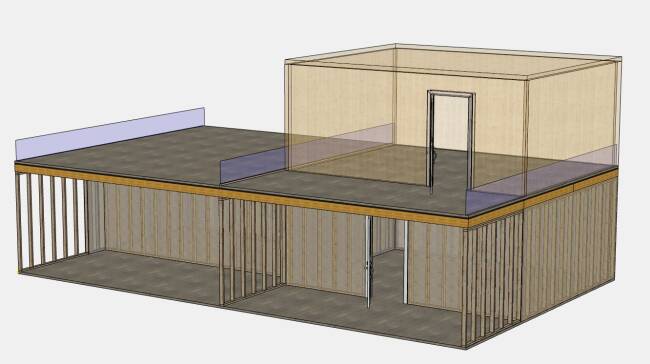

At the Forest Products Laboratory in Madison, WI, we are constructing a dedicated test rig with 5-ply CLT panels spanning wood-stud demising walls. Starting from a baseline condition, we will introduce variables that reflect real project conditions, including:

Landmark Research – and How You Can Help!

In partnership with the Canadian Wood Council and a broad group of industry collaborators, we are building a full-scale, data-driven map of the ceiling-to-ceiling flanking path so design teams can maintain continuous CLT and still meet ASTC requirements. The goal is straightforward: a clearly articulated, publicly accessible set of tested assemblies from which teams can select solutions—without defaulting to panel cuts or extensive dropped ceilings. Your input can help shape it. (Background on the research is here: HGC CLT Acoustics Study.)

Continuous CLT panels that run past demising walls can allow sound to travel laterally through the wood between suites, compromising code-required acoustic separation. Our research is focused on overcoming that challenge so projects can keep the mass timber visible – without losing control of noise or cost.

Mass timber has a powerful effect the moment someone walks into a space with exposed wood ceilings. After visiting hundreds of units over the years, that impression is unmistakable: standing in a living room with exposed CLT ceilings feels different. It borrows some of the calm of a wood cabin, even while in a busy multi-family building. Internationally, that impression has been reflected in the market – mass timber residential buildings are often positioned as higher-end and can command premium rents or sale prices. In Canada, however, mass timber has frequently been associated with affordable housing, in part because early adoption was driven by public funding aimed at innovative construction.

Well before residents experience that warm timber interior, design teams are making decisions that determine whether those ceilings can stay exposed or will disappear behind drywall. Where teams are less familiar with mass timber acoustics, managing acoustic risk with exposed CLT ceilings may warrant conservative measures: cutting CLT at every demising line, adding dropped nano-CLT ceilings, and other generous contingencies. Those strategies can protect performance, but they can also erode budgets to the point where the mass timber is value-engineered out entirely.

The core issue is that when CLT panels are continuous and exposed, design teams must consider not only the direct sound transmission through the floor/ceiling and wall assemblies, but also indirect (“flanking”) transmission through the ceiling-to-ceiling path via the continuous CLT between adjacent suites. Understanding – and controlling – that path is at the heart of this research.

FEATURE

New Acoustic Design Guidance and Research for Mass Timber Construction

For each configuration we’ll measure the vibration reduction index Kᵢⱼ for the ceiling-to-ceiling route (per ISO 10848) and feed it into ISO 12354 to quantify that path’s contribution to ASTC. We’ll also run full ASTC tests of the demising wall (inclusive of ceiling-to-ceiling flanking) and collect ASTC, AIIC and walking-vibration data of the demising floor/ceiling (i.e., measuring up/down) so the acoustics and structural narratives line up.

On toppings, the matrix is deliberately broad. We’ll test wet systems (concrete and gypsum-concrete at multiple thicknesses) and dry systems (plywood, cement board, proprietary materials), paired with underlayments across a range of thicknesses and dynamic stiffnesses. The sequencing is designed so we can compare like with like, and we’re managing curing/drying carefully so the numbers reflect the behaviour that designers will actually see after stabilization rather than just “day one in the lab.”

Different floor toppings (wet and dry systems)

Wall loading conditions

The effects of adjacent CLT (e.g., corridor panels)

The influence of modal resonances (e.g., furnished vs. unfurnished)

Bulkheads of varying sizes and configurations

What Are We Testing?

At the Forest Products Laboratory in Madison, WI, we are constructing a dedicated test rig with 5-ply CLT panels spanning wood-stud demising walls. Starting from a baseline condition, we will introduce variables that reflect real project conditions, including:

Landmark Research – and How You Can Help!

In partnership with the Canadian Wood Council and a broad group of industry collaborators, we are building a full-scale, data-driven map of the ceiling-to-ceiling flanking path so design teams can maintain continuous CLT and still meet ASTC requirements. The goal is straightforward: a clearly articulated, publicly accessible set of tested assemblies from which teams can select solutions—without defaulting to panel cuts or extensive dropped ceilings. Your input can help shape it. (Background on the research is here: HGC CLT Acoustics Study.)

Field Data that Shifted Our Understanding

Early lab testing and theory suggested that the ceiling-to-ceiling flanking path through continuous 5-ply CLT across a demising wall would limit performance to roughly ASTC-43 to ASTC-44, which is below code requirements across North America. Under those assumptions, acoustical consultants had little choice but to recommend cutting CLT panels at demising lines or installing dropped ceilings to achieve compliance.

Recent field testing across multiple buildings and configurations has shown that this picture is incomplete. Real projects rarely consist of bare CLT alone. Floor toppings, bulkheads, and adjacent construction all influence the ceiling-to-ceiling path – often in beneficial ways that were not captured in earlier lab work.

From those field investigations, several practical lessons have emerged for current projects:

Heavy toppings help. A heavyweight topping (e.g., concrete or gypsum-concrete) over an isolation layer on top of the CLT can significantly reduce ceiling-to-ceiling flanking, with measured performances in the ASTC-50+ range.

Dry toppings can work. A dry topping (e.g., plywood) over isolation material offers some reduction in ceiling flanking, although not as much as a wet topping. When combined with bulkheads on at least one side of the demising wall, ceiling-to-ceiling flanking can still land in the vicinity of ASTC-50 or higher.

More isolation isn’t always better. As the thickness of the isolation material increases, the topping’s ability to reduce flanking can diminish. With thicker isolation layers, performance can drift back toward the original ASTC-43 to 44 range.

Plan layouts to work with the structure. Higher acoustic targets can be met with continuous CLT by aligning unit layouts so that spaces with dropped ceilings or substantial bulkheads (e.g., kitchens and bathrooms) are mirrored across demising walls at the continuous-panel locations.

Where and When to Find Results

The project has moved beyond concept. Most of the funding is secured, partners are confirmed, and the rig is underway. Testing is scheduled to begin in spring 2026 and conclude by the end of 2026. Once the core matrix is complete, we will release the database for open industry use.

The deliverable will not be a dense report that requires translation. Instead, we will provide a design-ready database that links clear test descriptions to the ceiling-to-ceiling path’s contribution to ASTC. For readers who want more depth, we will also outline how the design ratings were derived from the Kᵢⱼ measurements.

Tailor-Made Results for the Design Community

This initiative is education-first, with the wood design community squarely in mind. If there is a floor or roof topping you specify regularly—wet or dry—or an underlayment you rely on, we encourage you to connect with us (email: sedwards@hgcacoustics.com). Likewise, sharing the ASTC and AIIC targets you are seeing by building type will help us prioritize the test matrix and present results in formats that can be used directly in practice.

As testing progresses, we will keep the community informed. The intent is simple: to help teams keep the wood exposed, keep projects on budget, and keep acoustic performance where it needs to be.