ASK AN EXPERT

Hydrogen embrittlement in mass-timber fasteners

What conditions lead to hydrogen embrittlement in mass-timber fasteners, and how can these risks be mitigated during installation?

In modern mass-timber construction, high-performance screws are essential for securing steel-to-wood and engineered-wood connections. Yet, the phenomenon of hydrogen embrittlement (HE) — in which hydrogen atoms penetrate high-strength steel and reduce ductility — can seriously undermine fastener reliability over time. For HE to manifest, three conditions must coincide: the presence of hydrogen, sustained load, and material susceptibility.

In practice, these conditions often arise from two sources. Internal HE (IHE) originates during production, through processes such as pickling or electroplating, while environmental HE (EHE) develops in service when corrosion occurs in humid or chlorinated environments. The latter highlights the importance of site conditions: prolonged exposure to moisture during construction can trigger corrosion, allowing hydrogen to diffuse into the screw, particularly if components are left unprotected before enclosure.

Beyond material factors, installation practices play a decisive role in preventing premature failures. Over-torquing, incorrect screw angles, or the use of impact drivers can induce residual stresses that act as sustained loads. Combined with wood swelling, rigid steel interfaces, or moisture ingress, these factors accelerate crack initiation and growth.

How can one determine the Fire Resistance Rating (FRR) and Sound Transmission Coefficient (STC) ratings for wood stud shear walls that include plywood on one or both sides and are finished with gypsum? To achieve a 1-hour rating, is it possible to use an existing tested gypsum assembly to meet both FRR and STC requirements and simply add plywood without affecting the ratings? Is there a better way to determine the FRR and STC ratings in this scenario?

Ensuring appropriate long-term protection, such as using membranes, sealants and other permanent protective systems, is crucial in safeguarding the durability and reliability of the connection.

Mitigation relies on controlling what happens on-site: ensuring proper torque, managing exposure to moisture before and after assembly, and selecting fasteners and coatings suitable for the expected exposure class. When design, installation, and moisture management align, the durability of timber connections — and the performance of the entire structure — can be confidently ensured.

Read more here

ASK AN EXPERT

Engineered wood products in mid-rise buildings

What are the main things to consider when designing a mid-rise project using engineered wood products?

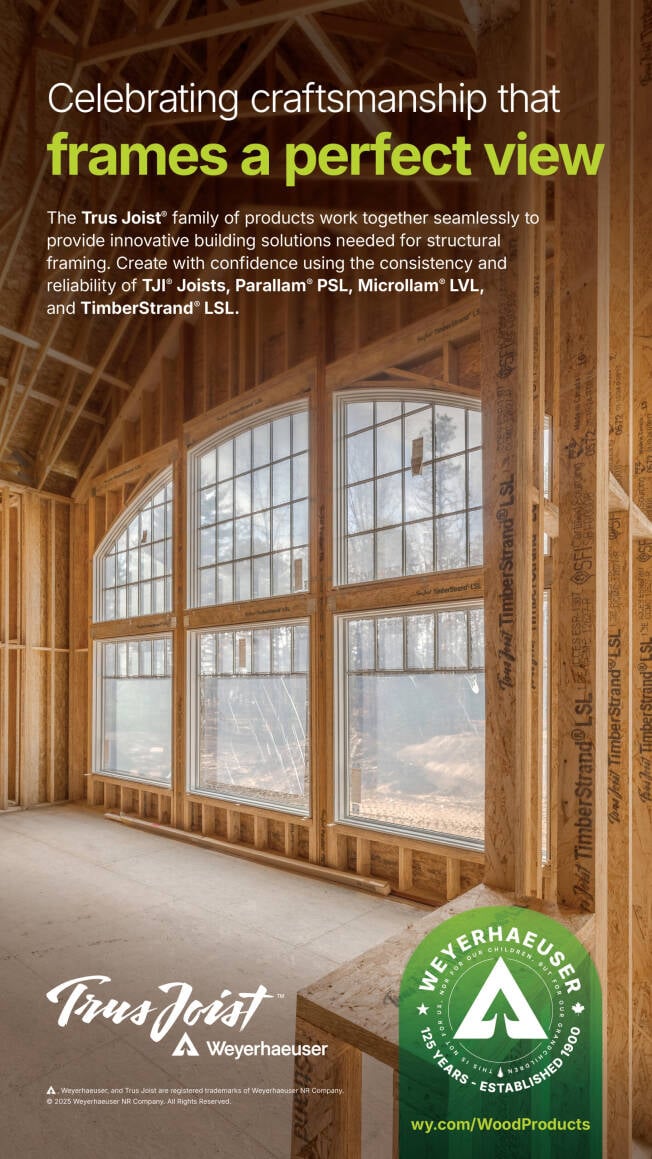

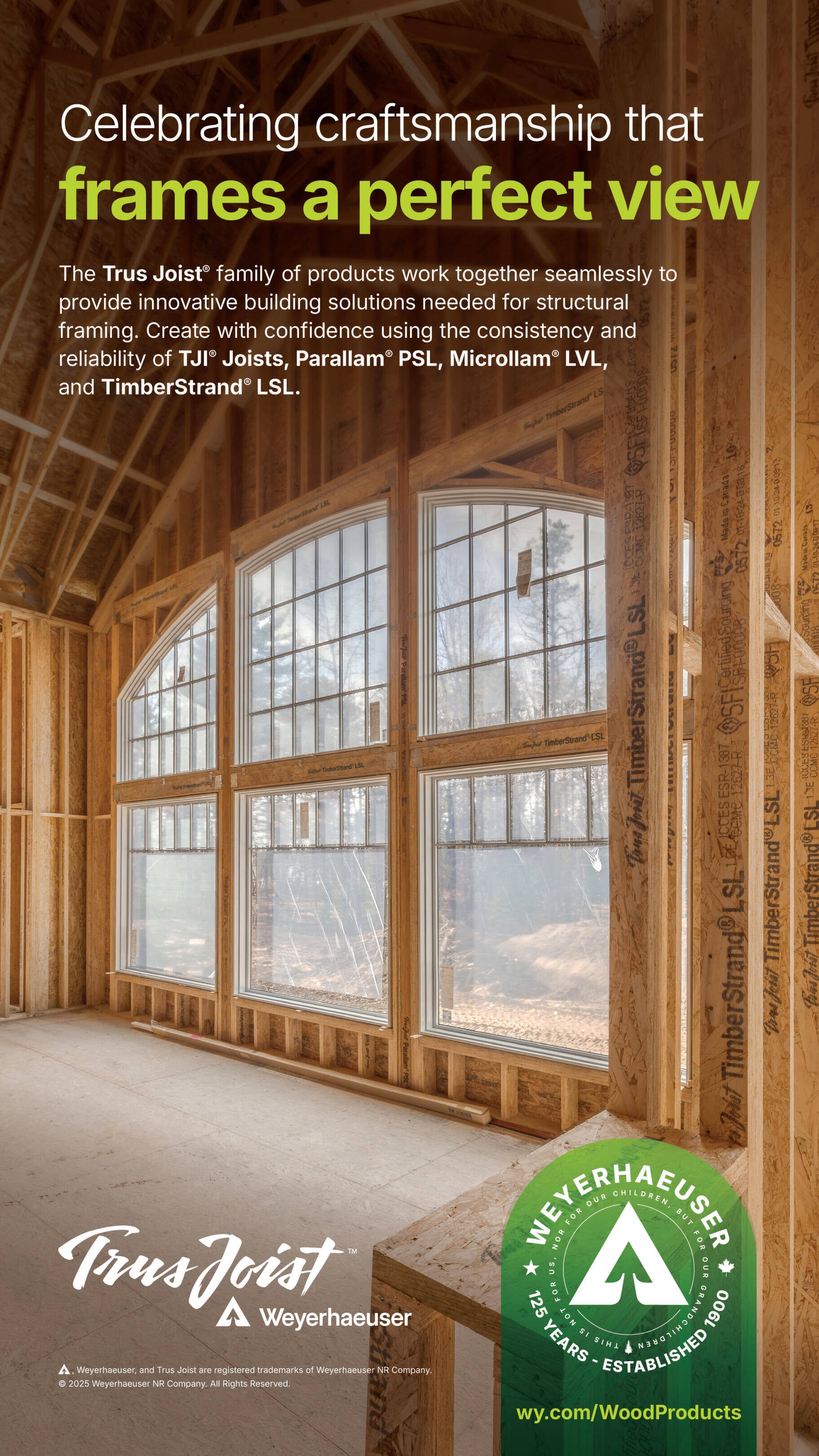

Designing a successful mid-rise project with engineered wood products (EWP) is about more than simply selecting a floor system from a catalogue. It requires aligning structural performance, constructability, and long-term reliability from the earliest stages of design through to on-site execution. Four key considerations can help guide that process—starting with choosing the right products for each application, then simplifying installation and inspection, working closely with experienced EWP suppliers, and carefully evaluating any proposed substitutions to ensure your project goals are fully met.

Key 1: Choosing Products for Performance

Considering the unique properties and characteristics of individual products in specification – in other words, using the right products in the right place – can help address critical structural challenges for mid-rise buildings. For example, using the depth stability of TimberStrand® LSL in rim board applications can reduce vertical building movement with moisture content changes, while the tight allowable fastener spacing into edges provides for easy transfer of lateral loads between storeys.

Using our TJ-Pro Rating system to estimate floor performance before construction can help you meet customer expectations, while maintaining a cost-competitive floor system.

Key 2: Simplify Installation and Inspection

Any steps you can take to standardize and simplify installation will reduce the potential for errors on site. Beyond the standard installation details for EWP, you might choose to specify thicker one-piece beams and rim board instead of multi-ply members, saving time and labour on site, meanwhile simplifying site inspections. pre-fabricated or pre-cut components, floor and wall panels, and modular construction methods all have the potential to reduce construction time.Coordinating with and meeting trades on site before they begin their work is always a good strategy to avoid potentially difficult or costly repairs.

Key 3:Collaborate with an Experienced Supplier and Manufacturer

Engaging the expertise of experienced EWP specialists early in the design phase can help you get the most out of EWP products and systems. Ongoing support from knowledgeable suppliers can help a project succeed.Most importantly, good communication between project professionals and experienced EWP suppliers can identify and adjust potentially troublesome areas before construction.

Key 4: Evaluate Alternatives Carefully

In the rush to construct these jobs, requests to substitute alternative materials are common. When considering these requests, be sure that your client’s expectations will still be met not only on paper, but through quality, service, and support before, during, and after construction. Weyerhaeuser has developed tools, literature, and people to help with these and many other technical topics.

How can one determine the Fire Resistance Rating (FRR) and Sound Transmission Coefficient (STC) ratings for wood stud shear walls that include plywood on one or both sides and are finished with gypsum? To achieve a 1-hour rating, is it possible to use an existing tested gypsum assembly to meet both FRR and STC requirements and simply add plywood without affecting the ratings? Is there a better way to determine the FRR and STC ratings in this scenario?

For more information, visit our Specification Center

Wood Products Specification Center | Weyerhaeuser

Wood Products Specification Center | Weyerhaeuser

ASK AN EXPERT

Hydrogen embrittlement in mass-timber fasteners

What conditions lead to hydrogen embrittlement in mass-timber fasteners, and how can these risks be mitigated during installation?

In modern mass-timber construction, high-performance screws are essential for securing steel-to-wood and engineered-wood connections. Yet, the phenomenon of hydrogen embrittlement (HE) — in which hydrogen atoms penetrate high-strength steel and reduce ductility — can seriously undermine fastener reliability over time. For HE to manifest, three conditions must coincide: the presence of hydrogen, sustained load, and material susceptibility.

In practice, these conditions often arise from two sources. Internal HE (IHE) originates during production, through processes such as pickling or electroplating, while environmental HE (EHE) develops in service when corrosion occurs in humid or chlorinated environments. The latter highlights the importance of site conditions: prolonged exposure to moisture during construction can trigger corrosion, allowing hydrogen to diffuse into the screw, particularly if components are left unprotected before enclosure.

Beyond material factors, installation practices play a decisive role in preventing premature failures. Over-torquing, incorrect screw angles, or the use of impact drivers can induce residual stresses that act as sustained loads. Combined with wood swelling, rigid steel interfaces, or moisture ingress, these factors accelerate crack initiation and growth.

Mitigation relies on controlling what happens on-site: ensuring proper torque, managing exposure to moisture before and after assembly, and selecting fasteners and coatings suitable for the expected exposure class. When design, installation, and moisture management align, the durability of timber connections — and the performance of the entire structure — can be confidently ensured.

Ensuring appropriate long-term protection, such as using membranes, sealants and other permanent protective systems, is crucial in safeguarding the durability and reliability of the connection.

Read more here

ASK AN EXPERT

Engineered wood products in mid-rise buildings

What are the main things to consider when designing a mid-rise project using engineered wood products?

Designing a successful mid-rise project with engineered wood products (EWP) is about more than simply selecting a floor system from a catalogue. It requires aligning structural performance, constructability, and long-term reliability from the earliest stages of design through to on-site execution. Four key considerations can help guide that process—starting with choosing the right products for each application, then simplifying installation and inspection, working closely with experienced EWP suppliers, and carefully evaluating any proposed substitutions to ensure your project goals are fully met.

Key 1: Choosing Products for Performance

Considering the unique properties and characteristics of individual products in specification – in other words, using the right products in the right place – can help address critical structural challenges for mid-rise buildings. For example, using the depth stability of TimberStrand® LSL in rim board applications can reduce vertical building movement with moisture content changes, while the tight allowable fastener spacing into edges provides for easy transfer of lateral loads between storeys.

Using our TJ-Pro Rating system to estimate floor performance before construction can help you meet customer expectations, while maintaining a cost-competitive floor system.

Key 2: Simplify Installation and Inspection

Any steps you can take to standardize and simplify installation will reduce the potential for errors on site. Beyond the standard installation details for EWP, you might choose to specify thicker one-piece beams and rim board instead of multi-ply members, saving time and labour on site, meanwhile simplifying site inspections. pre-fabricated or pre-cut components, floor and wall panels, and modular construction methods all have the potential to reduce construction time.Coordinating with and meeting trades on site before they begin their work is always a good strategy to avoid potentially difficult or costly repairs.

Key 3:Collaborate with an Experienced Supplier and Manufacturer

Engaging the expertise of experienced EWP specialists early in the design phase can help you get the most out of EWP products and systems. Ongoing support from knowledgeable suppliers can help a project succeed.Most importantly, good communication between project professionals and experienced EWP suppliers can identify and adjust potentially troublesome areas before construction.

Key 4: Evaluate Alternatives Carefully

In the rush to construct these jobs, requests to substitute alternative materials are common. When considering these requests, be sure that your client’s expectations will still be met not only on paper, but through quality, service, and support before, during, and after construction. Weyerhaeuser has developed tools, literature, and people to help with these and many other technical topics.

For more information, visit our Specification Center

Wood Products Specification Center | Weyerhaeuser

Wood Products Specification Center | Weyerhaeuser